1.Consult our Industry Expert to discuss your requirements

Trusted By

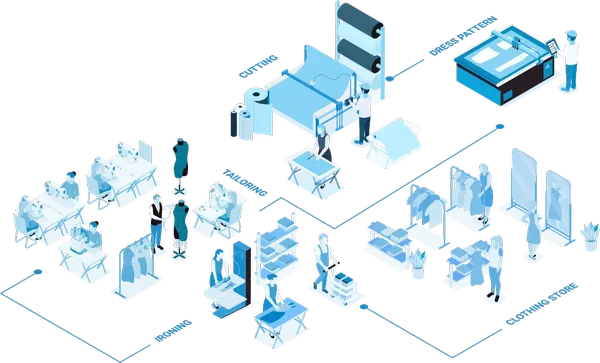

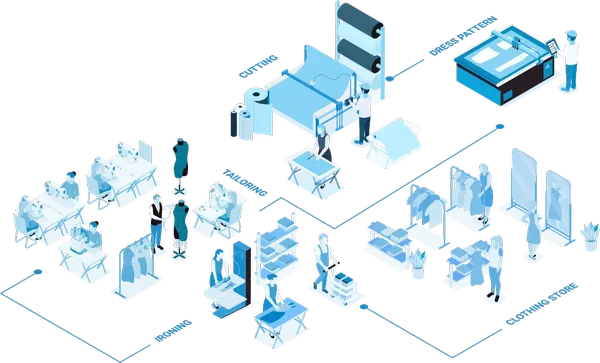

smart erp for Garment Manufacturing

Simplify workflows for even the most complex garment manufacturing processes with VasyERP's custom solution for apparel manufacturers. From procurement, sales, suppliers, and bills of materials (BOM), to inventory, batched stocks, CRM, and maintenance job sheets, ERP for garment manufacturing has modules to automate and cover all your business needs. Track progress and get all reports on intuitive and interactive dashboards.

Keys to Successful Garment Manufacturing

Analytics for Smart Decision Making

With analytics provided by the garment ERP, you will be armed with insights to make decisions that prove to be highly profitable for your business.

Flawless and Lean Processes

Our custom ERP solution for garment manufacturers is designed to eliminate process redundancies and establish optimal workflows.

Integrated

Modules

Our ERP connects all your departments from accounting, CRM, and Sales to production units and warehouses with completely integrated modules.

Top Features of erp for Garment manufacturing

Sewing success together with Industry-specific features of our ERP for Apparel Businesses

Production Management

Cost Management

Planning Management

Materials Management

Asset Management

Quality Control Management

Inventory Management

Stock Category Management

Product Information Management

Supply chain management

Purchase Orders

Logistics Optimization

Test Certificate Management

Plant Maintenance Scheduling

Finance Management

Process Automation

AI Integrations

Bills of Materials

Warehouse Management

Supplier Management

Retail POS

Integrated Accounting

Business Intelligence

CRM Module

Couldn’t Find the

Feature You Need?

Couldn’t Find the Feature You Need?

don't worry

We Will Get It Custom-Made For You!

don't worry

We Will Get It

Custom-Made For You!

Contact our team for your specific requirements and we will add the features you need and create a custom ERP Solution for your garment manufacturing unit!

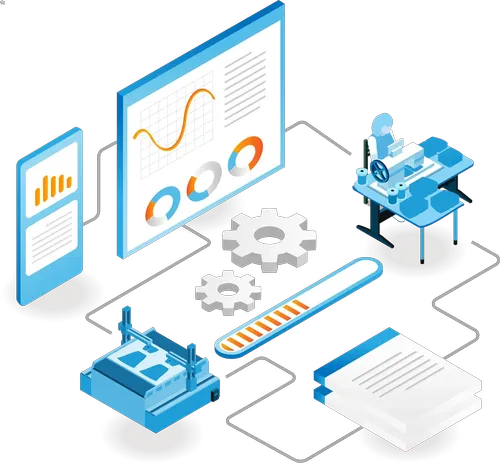

Analytics and Reporting

Get All Reports for Better Decision Making and Insights

Reports & Analytic Dashboards

Provides a range of reports and dashboards for analyzing various aspects of the manufacturing process

Process/Production Reports

Detailed reports on the production processes help identify bottlenecks and optimize workflows

Sales Reports

Generates reports on sales performance, customer behavior, and market trends to support strategic decision-making.

Quality Control Report

Monitor and evaluate the adherence to quality standards at various stages of production and flag quality issues

Comparative Reports

Compare sales and profitability across different products, and periods, providing insights for strategic planning.

Dispatch Reports

Monitors and reports on the dispatch of finished goods, ensuring timely and accurate deliveries.

Compliance Reporting

Tracks compliance metrics and helps avoid penalties. Reports on industry-specific compliance measures.

Supplier/Vendor Reports

Real-time reports on negotiations, performance, and collaborations with suppliers and vendors

Brand Analysis Report

Analyzes the performance of different product brands in the market, helping in strategic brand management.

Provides a range of reports and dashboards for analyzing various aspects of the manufacturing process

Detailed reports on the production processes help identify bottlenecks and optimize workflows

Generates reports on sales performance, customer behavior, and market trends to support strategic decision-making.

Monitor and evaluate the adherence to quality standards at various stages of production and flag quality issues

Compare sales and profitability across different products, and periods, providing insights for strategic planning.

Monitors and reports on the dispatch of finished goods, ensuring timely and accurate deliveries.

Tracks compliance metrics and helps avoid penalties. Reports on industry-specific compliance measures.

Real-time reports on negotiations, performance, and collaborations with suppliers and vendors

Analyzes the performance of different product brands in the market, helping in strategic brand management.

Keys benefits of erp for garment manufacturing

Fabric to Fashion: A custom ERP that optimizes all processes of your garment manufacturing business

Lean waste management

- Efficiently deal with Fabric Scraps, rejected goods, or production leftovers with advanced lean manufacturing capabilities

Robust Quality Control

- Monitor and evaluate various quality control metrics like production quality, defect rate, return rate, and corrective measures

Uninterrupted supply chains

- Impeccable supply chains with robust demand forecasting and seamless supplier communication channels

Full Regulatory Compliance

- Safeguard your apparel manufacturing unit from unwanted penalties or regulatory actions with compliance monitoring features

Effective cost Management

- Reduce labor costs with better processes that eliminate redundant processes with automation and lower manufacturing costs

Improved production quality

- Achieve faster turnaround with improved planning, expedited processes, real-time visibility, and proactive measures that eliminate manufacturing hurdles.

Process of Implementation

Improved Process, Increased Profits: Scale Manufacturing Businesses to Great Heights

Consult our Industry Expert to discuss your requirements

Discuss project feasibility and customization options

Support for flawless implementation and employee training

Get guidance on the right solutions for your needs

Get quality software delivered on time, on budget

VasyERP Addresses All ERP

Implementation Challenges

Enterprise Software for retail

Manufacturers with retail outlets can bank on the VasyERP Gold solution for Managing their retail outlets. Enterprise retail solutions like VasyERP help manufacturers in multi-channel retailing, POS management, customer interactions, and loyalty management.

experience Now

why vasyerp gold?

A tailored ERP solution addressing manufacturing industry challenges

All-in-one ERP for Manufacturing

4.8 Google Rating

Fastest Implementation

3 Months of Customization

Third-party API Integrations

Cost-effective solution

Best Pricing in the market

Robust Cloud Security

Server Cost Included

Improvements in the Bottom line

Dedicated Account Manager

E-Lite Plan Included

Featured Case Studies

Real Results, Real Impact: Learn how our ERP revolutionized operations and boosted productivity

VasyERP Working for You to Build Your Business Super-Efficient

Get product demo so you’re confident it’s the right fit. stay focused on what you’re good at and let us improve your store experience and efficiency.

17,000+ Customers

4.8 Google Review

FAQ! Need Help?

We've got you covered

The ERP software for the garment manufacturing industry can consolidate data and processes from various departments into a centralized database. This makes it easier for all to access the data whenever required and speeds up decision-making. For example: With easily accessible data a product manager will exactly know when the maintenance team has planned scheduled repairs and therefore he/she can plan their production hours accordingly to keep a minimum impact on production output.

The ERP also takes care of intricate processes such as Bills of materials, supplier management, inventory control, warehouse, and production quality control. Managing these processes manually is prone to errors and inefficiencies and therefore, using ERP ensures flawless workflows of the above-mentioned processes.

Challenge 1: Supply chain management complexities

Solution: ERP software provides visibility across the supply

chain, tracking inventory, forecasting demand, and

optimizing procurement processes.

Challenge 2: Inventory management issues

Solution: ERP systems offer real-time tracking, automated

replenishment, and demand forecasting to minimize stockouts

and overstock situations.

Challenge 3: Production planning and scheduling problems

Solution: ERP software facilitates capacity planning,

scheduling, and resource allocation to streamline

workflows and minimize production bottlenecks.

Challenge 4: Quality Control issues

Solution: ERP systems integrate quality management modules to

monitor production parameters and enforce

quality standards throughout the manufacturing process.

Challenge 5: Compliance with regulations

Solution: ERP software enables documentation of regulatory

requirements, audit trails, and reporting

capabilities to maintain compliance.

Challenge 6: Data visibility and analytics

Solution: ERP systems provide comprehensive reporting and

analytics tools for real-time insights into key

performance indicators (KPIs) and process improvement.

Challenge 7: Cost reduction

Solution: ERP software optimizes processes and resource

utilization, minimizing operational costs and

improving profitability.

Challenge 8: Managing industrial waste

Solution: ERP software optimizes production processes and

inventory management, minimizing waste generation

and facilitating sustainable practices through predictive analytics

and waste tracking modules.

- Identify Manufacturing Process Requirements: Understand the intricacies of garment production, including supply chain management, inventory tracking, production planning, and quality control. Look for an ERP solution that addresses these specific needs effectively.

- Scalability: As your garment business grows, so will your operational needs. Select an ERP system that can scale alongside your enterprise, accommodating increased production volumes, expanded product lines, and additional manufacturing facilities.

- Integration: Garment manufacturing involves various interconnected processes such as design, production, inventory management, accounting module, and sales. Ensure that the chosen ERP seamlessly integrates with existing systems like CAD software for design, production machinery, and sales platforms.

- User-Friendliness: Garment production teams may include individuals with diverse technical skills. Choose an ERP system with an intuitive interface and user-friendly features that enable your team to navigate and utilize the software effortlessly.

- Expertise of the Provider: Research ERP software providers with a proven track record in serving the garment industry. Look for vendors who understand the unique challenges and requirements of garment manufacturing, such as seasonality, rapid product turnover, and fashion trends.

- Customization: The garment industry often requires flexibility to accommodate changing fashion trends, production techniques, and customer demands. Assess the level of customization offered by the ERP system to tailor processes and workflows according to your specific requirements.

- Consideration of Costs: Evaluate both the initial implementation costs and ongoing maintenance expenses associated with the ERP system. Consider factors such as licensing fees, implementation services, training, and support. Opt for a solution that offers a balance between cost and features while providing a positive return on investment.

- Vendor Evaluation: Ask questions about customization options, scalability, integration capabilities, and user support. Assess the vendor's responsiveness, expertise, and willingness to address your specific needs.