1.Consult our Industry Expert to discuss your requirements

Trusted By

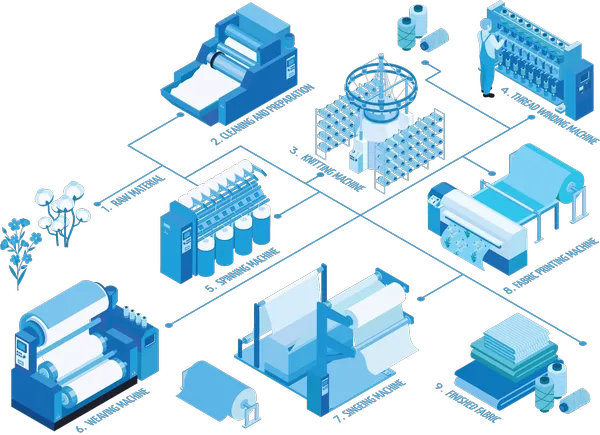

Custom Textile ERP Software

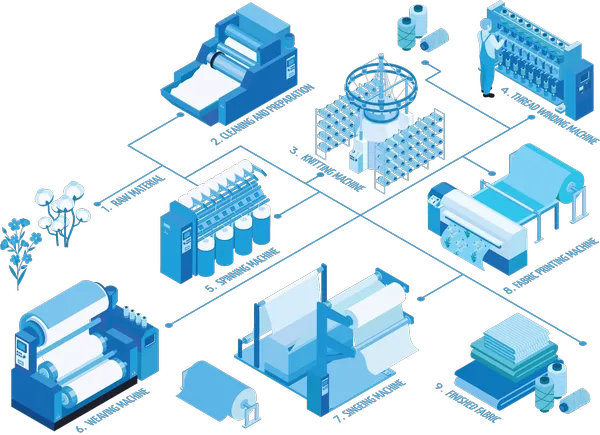

From standalone yarn-to-fabric, cotton-to-yarn, or fabric-to-dying textile segments to textile manufacturing units that combine them all, VasyERP's fully customizable ERP is a single solution for managing all segments of the textile and spinning industry. Once you deploy our textile ERP software, you can see how easily you can automate your key processes from procurement to production and warehousing and visualize everything on an interactive dashboard.

Keys to Successful Textile Manufacturing

Smart

Analytics

Our textile ERP software has a robust reporting and analytical system that helps you make the most profitable decisions regarding production, inventory, and customers.

Zero-Waste

Manufacturing

Eliminate processes that are monotonous, and less productive and replace them with lean workflows that ensure zero waste of time, money, and effort with industry-grade textile software.

Integrated

Modules

One ERP serves for all textile manufacturing departments from production, warehouse, and logistics to sales, accounting, and CRM with flawlessly integrated modules.

Top Features of Textile Manufacturing Software

Spin the thread of success with features designed specifically for textile manufacturers

Bales or Lot-Wise Production

Process Monitoring

Tracking (Inward/Outward)

Procurement

Planning Management

Materials Management

Cost Management

Expenditure Analysis

Finance Management

Inventory Management

Stock Category Management

Asset Management

Supply chain Optimization

Sales Orders

Quality Control Management

Process Automation

Technology Integrations

Bills of Materials

Compliance Management

Plant Maintenance Scheduling

Warehouse Management

CRM Module

Automatic Reconciliation

E-way Bill

Outsourced/Contractor Module

Supplier Management

Business Intelligence

Couldn’t Find the

Feature You Need?

Couldn’t Find the Feature You Need?

don't worry

We Will Get It Custom-Made For You!

don't worry

We Will Get It

Custom-Made For You!

Contact our team for your specific requirements and we will add the features you need and create a custom ERP Solution for your textile manufacturing unit!

Analytics and Reporting

Weave easily through the complexity of the textile manufacturing processes with valuable insights at your fingertips

Production Reports

Reports that present a complete view of processes from procurement to cutting and tailoring.

Financial Reports

Reports about Break down the costs involved in production, labor costs, expenses, and P&L statements,

Sales Reports

Reports that guide textile manufacturers through their sales data, sales figures, and performance.

Inventory Reports

Reports detailing textile stock, under-process stock, and finished goods in the warehouse or in transit

Quality Control Reports

Reports showing metrics about cutting, tailoring, and ironing quality standards.

Compliance Reporting

Reports in formats that help the textile industry deal with compliance and protocols during regulatory inspections.

Reports that present a complete view of processes from procurement to cutting and tailoring

Reports about Break down the costs involved in production, labor costs, expenses, and P&L statements

Reports that guide textile manufacturers through their sales data, sales figures, and performance.

Reports detailing textile stock, under-process stock, and finished goods in the warehouse or in transit

Reports showing metrics about cutting, tailoring, and ironing quality standards.

Reports in formats that help the textile industry deal with compliance and protocols during regulatory inspections.

Keys benefits of erp for Textile manufacturing

Yarns of Progress, Fabrics of Success: A custom textile ERP software built for textile manufacturers

Lean Manufacturing Processe

- Eliminate waste of time, processes, and efforts and efficiently deal with rejected cotton bales, production leftovers, scrap, etc

Advanced Quality Control

- Check quality parameters and metrics, deploy preventive and corrective quality control measures, and reduce defect rate or downtime

Resilient Supply Chains

- Control your warehouse inventory, stock flow to distributors, and forecast demand accurately to ensure uninterrupted supply chains

Be Fully-Compliant

- No unwanted issues with regulatory bodies with maximum compliance adherence and monitoring and standard documentation

Cost Savings

- Quality processes that bring full productivity potential and elimination of repetitive workflows with automation reduce costs

Enhanced Production

- Waste reductionQuicker functions and removal of production bottlenecks lead to better production capacities and faster turnaround

Process of Implementation

Simple, Fast and No-Hassle Implementation by VasyERP Experts

Consult our Industry Expert to discuss your requirements

Discuss project feasibility and customization options

Support for flawless implementation and employee training

Get guidance on the right solutions for your needs

Get quality software delivered on time, on budget

VasyERP Addresses All ERP

Implementation Challenges

Enterprise Software for retail

Manufacturers with retail outlets can bank on the VasyERP Gold solution for Managing their retail outlets. Enterprise retail solutions like VasyERP help manufacturers in multi-channel retailing, POS management, customer interactions, and loyalty management.

experience Now

why vasyerp gold?

A tailored ERP solution addressing manufacturing industry challenges

All-in-one ERP for Manufacturing

4.8 Google Rating

Fastest Implementation

3 Months of Customization

Third-party API Integrations

Cost-effective solution

Best Pricing in the market

Robust Cloud Security

Server Cost Included

Improvements in the Bottom line

Dedicated Account Manager

E-Lite Plan Included

Featured Case Studies

Real Results, Real Impact: Learn how our ERP revolutionized operations and boosted productivity

VasyERP Working for You to Build Your Business Super-Efficient

Get product demo so you’re confident it’s the right fit. stay focused on what you’re good at and let us improve your store experience and efficiency.

17,000+ Customers

4.8 Google Review

FAQ! Need Help?

We've got you covered

Textile ERP has modules for every function that is under operation in textile mills. The key modules take care of procurement, production, inventory, accounting, financials, compliance, maintenance, supply chain, warehouse, and customers. With customizable textile ERP software solutions, manufacturers can add or drop the features that they need or don’t need as per their respective manufacturing unit requirements.

ERPs work by automation, and automation mitigates redundancies and waste processes. Automation brings lean manufacturing into existence and thus helps manufacturers save big on time, effort, and money.

The ERP for textiles also covers the business intelligence aspect. Analytics are very prominent today in the world where data exerts a huge influence on how businesses work, earn, and stay ahead of the curve. Textile manufacturers can get reports and analytics with easy-to-visualized reports about the key happenings in their business (from sales to dispatch and financial reports to inventory status). These reports help textile manufacturers take timely action to improve their businesses.

From small textile units to medium and large-scale textile manufacturers, textile ERP is adaptable and scalable to cater to all sizes of textile manufacturing businesses.

Challenge 1: Complex Supply Chain Management

Solution: ERP for textile eases supply chain operations with

optimized route mapping, inward/outward tracking, and warehouse

management

Challenge 2: Quality Assurance

Solution: Ensure quality control with quality check

parameters and inspection tools.

Challenge 3: Machinery Downtime

Solution: Automated proactive maintenance scheduling to

maximize uptime.

Challenge 4: Inefficient Communication

Solution: Textile software offers a centralized platform for

inter-departmental communication, file sharing, etc.

Challenge 5: Financial Management

Solution: Generates accurate financial reports, GST reports,

filings, expense statements, P&L statements, etc.

Challenge 6: Demand Forecasting

Solution: Utilizes historical data to predict market

requirements and plan production accordingly

Challenge 7: Cost Management

Solution: With the automation of redundant processes and lean

manufacturing to reduce waste, the ERP for textile leads to

significant cost savings

Challenge 8: Inventory Management

Solution: Stock operations simplified with inventory,

warehousing, stock

verification, and barcoding features.

Challenge 9: Supplier and Customer Relationship Management

Solution: Collect data of suppliers and customers in the

contact module and use them for promotions or faster connection with

these stakeholders.

Challenge 10: Procurement management

Solution: Helps strategize raw material requirements,

generates Bills of Materials, and automated reorder points

- Know what you need: Ignorance is not bliss when it comes to selecting textile ERP. You may lose money if you don’t know exactly what your current requirements are, and what type of supply chain features, inventory features, or accounting modules you need to keep your textile unit running profitably. Understand the intricacies of production planning, and quality control. Seek an ERP that addresses all pain points and your specific needs.

- Integrations and modules: Efficient Textile manufacturing is a sum total of multiple processes going on in a synchronized way. This means, your procurement, production, inventory, supply chain, CRM and finance must be interconnected for a smooth flow of data between these processes. Such integration is the only way you can keep all departments on the same page and remove departmental or process silos. involves various interconnected processes such as design, production, inventory management, accounting module, and sales. Ensure that the chosen textile ERP has seamless integrations.

- User-Friendliness: Not all your staff will be super tech savvy and any ERP that demands a lot of learning curve can repel your staff. With complicated dashboards, your staff may face issues with understanding how to read the data on the screen. This will fail the purpose. Ensure your textile manufacturing software provider guarantees an intuitive and user-friendly interface that can be navigated without hiccups.

- Expertise of the Provider: Check how much experience, expertise, domain knowledge, and understanding of the industry challenges your ERP provider has and whether they would be able to serve you. This evaluation can be done just by going through their demo and asking them questions. Ask about how their ERP will tackle seasonal fluctuations, supply chain complexities, etc.

- Customization: In textile, though every mill has the same processes the scale or workflows can be different. Custom features that specifically address this disparity and uniqueness are essential. Therefore, simply ask your textile ERP provider if they provide custom features or not. Consider the refusal of custom features as a red flag. However, if they explain the feasibility issues due to certain limitations then pay attention, as they may be rational. It means that there are actually some features that cannot be custom-implemented due to certain limitations.

- Consideration of Costs: Finally, the cost is where things are finally settled. Evaluate the cost quotations, but also keep quality in mind. Vendors with great teams, better responsiveness, and experience will also demand a premium on their services but the value you receive will be equally greater. Understand implementation costs, operational costs, licensing fees, training and support costs, etc. before you make the final investment.