1.Consult our Industry Expert to discuss your requirements

Trusted By

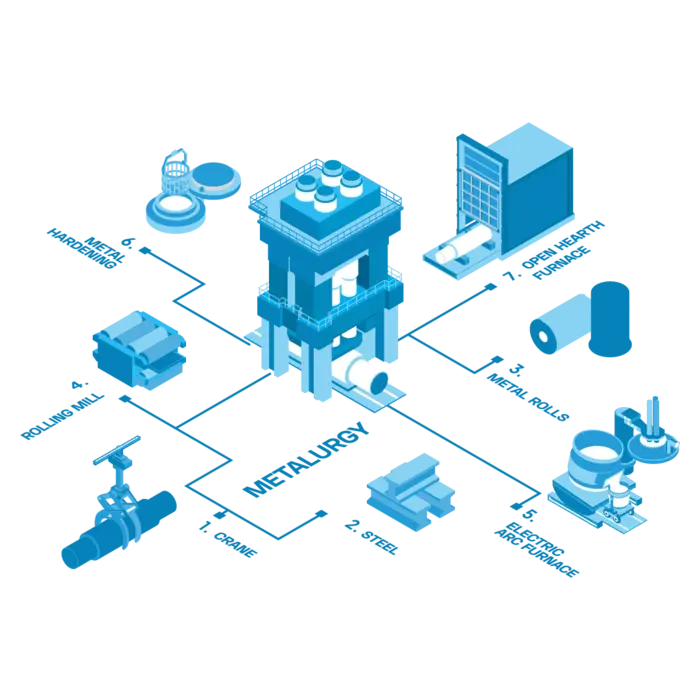

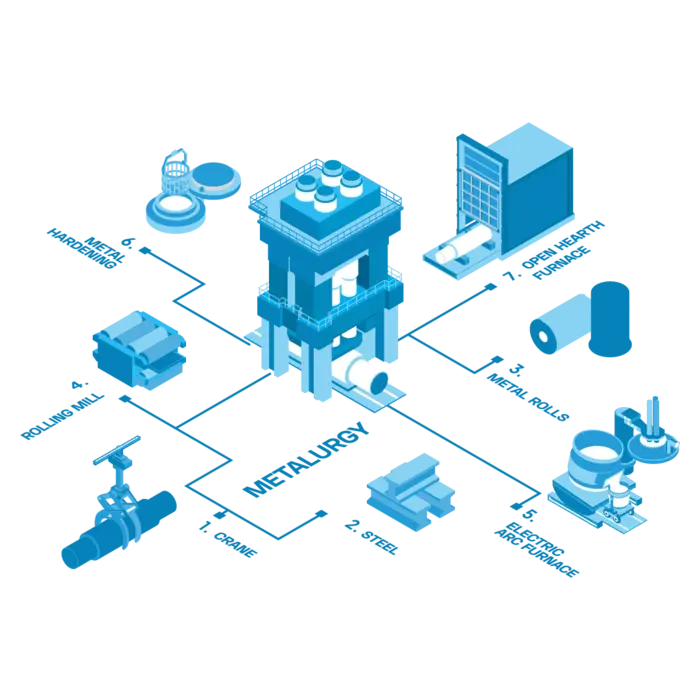

Custom Steel ERP Software

Complete ERP solution for the steel and metallurgy industry

Integrated ore-to-steel, scrap-to-product, or alloy-to-fabrication segments

Customizable to fit the specific needs of steel manufacturers

Meet ERP that's built to withstand the pressures of steel inventory management

Visualize all processes & workflows on a central dashboard

Keys to Successful Steel Manufacturing

Smart

Analytics

Our steel industry ERP software features a comprehensive reporting and analytical module that generates 100+ reports that empower you to make profitable data-driven decisions for procurement, production, and inventory.

Lean

Manufacturing

Make your operations leaner by eliminating inefficient processes. Implement productive workflows with our industry-specific steel manufacturing software, which helps you minimize the waste of labor, money, and resources.

Integrated

Modules

Our all-in-one ERP solution optimizes every aspect of steel manufacturing. From raw material procurement, steel production, and quality control to supply chain management, sales, accounting, and CRM, VasyERP has flawlessly integrated modules.

Top Features of Steel

Manufacturing ERP

Mold success with specially designed features of our precision-engineered ERP for steel manufacturers

Dashboard

Planning Management

Batch or Heat-wise Production

Process Monitoring

Production Tracking

Materials Management

Procurement

Inventory Management

Stock Category Management

Cost Management

Inbuilt Accounting

Asset Management

Supply chain Optimization

WIP Tracking

Quality Control Management

.webp)

TQM (Total Quality Management)

Process Automation

Technology Integrations

Bills of Materials

Compliance Management

Plant Maintenance Scheduling

Warehouse Management

Logistics Management

CRM Module

E-way Bill

Couldn’t Find the

Feature You Need?

Couldn’t Find the Feature You Need?

don't worry

We Will Get It Custom-Made For You!

don't worry

We Will Get It

Custom-Made For You!

We can customize the features that you need and develop a custom ERP Solution for your steel manufacturing unit!

Analytics and Reporting

Melt away inefficiencies and mold a stronger future with valuable insights that drive data-based decision-making

Planning & Forecasting Reports

Reports that present valuable analytics for demand forecasting, scheduling, resource allocation, and material requirements planning.

Financial Reports

Reports about cost and expenditure analysis, budgeting, profit analysis, P&L statements, labor costs, energy costs, etc.

Supply Chain Reports

Reports detailing supplier performance, procurement metrics, distribution, and dispatch reports.

Inventory Reports

Real-time reports about inventory levels, low stock alerts, raw material consumption reports, stock transfer reports, under-process stock reports, and finished goods reports.

Quality Control Reports

Reports that showcase quality metrics, material traceability reports, and other quality assurance-related reports.

Compliance Reports

Reports that help steel manufacturers deal with regulatory inspections, plant audits, and other compliance requirements.

Sales Reports

Reports that provide steel manufacturers with a complete overview of sales, sales analytics, and performance

Production Reports

ERP for steel by VasyERP generates production-related reports like material usage, current production status, machinery run times, etc.

Reports that present valuable analytics for demand forecasting, scheduling, resource allocation, and material requirements planning.

Reports about cost and expenditure analysis, budgeting, profit analysis, P&L statements, labor costs, energy costs, etc.

Reports detailing supplier performance, procurement metrics, distribution, and dispatch reports.

Real-time reports about inventory levels, low stock alerts, raw material consumption reports, stock transfer reports, under-process stock reports, and finished goods reports.

Reports that showcase quality metrics, material traceability reports, and other quality assurance-related reports.

Reports that help steel manufacturers deal with regulatory inspections, plant audits, and other compliance requirements.

Reports that provide steel manufacturers with a complete overview of sales, sales analytics, and performance

ERP for steel by VasyERP generates production-related reports like material usage, current production status, machinery run times, etc.

Keys benefits ERP for the Steel Industry

Blast the furnace of growth with a custom ERP solution built

Zero-waste Manufacturing

- Minimize time inefficiencies

- Implement intelligent workflows

- Manage rejected steel products

Accelerated Production

- Faster production processes

- Eliminate functional bottlenecks

- Resolve production constraints

Full Regulatory Compliance

- Mitigate compliance challenges

- Comprehensive documentation

- Meet regulatory standards

Faster Time to Market

- Prediction accuracy

- Low downtime & maximum productivity

- Minimum defects

Advanced Quality Assurance

- Monitor quality indicators

- Establish proactive quality standard

- Implement remedial y measures

Resilient Supply Chains

- Optimized inventory

- Smoother stock-flows

- Robust & consistent supply chains

Cost Savings

- Automation for cost-effectiveness

- No repetitive process

- Reduced admin costs

Financial Growth

- Higher revenues

- Top profit margins

- Improved cash flow

Process of Implementation

Simple, Fast and No-Hassle Implementation by VasyERP Experts

Consult our Industry Expert to discuss your requirements

Discuss project feasibility and customization options

Support for flawless implementation and employee training

Get guidance on the right solutions for your needs

Get quality software delivered on time, on budget

VasyERP Addresses All ERP

Implementation Challenges

Enterprise Software for retail

Manufacturers with retail outlets can bank on the VasyERP Gold solution for Managing their retail outlets. Enterprise retail solutions like VasyERP help manufacturers in multi-channel retailing, POS management, customer interactions, and loyalty management.

experience Now

why vasyerp gold?

A tailored ERP solution addressing manufacturing industry challenges

All-in-one ERP for Manufacturing

4.8 Google Ratings

Fastest Implementation

3 Months of Customization

Third-party API Integrations

Cost-effective solution

Best Pricing in the market

Robust Cloud Security

Server Cost Included

Improvements in the Bottom line

Dedicated Account Manager

E-Lite Plan Included

Featured Case Studies

Real Results, Real Impact: Learn how our ERP revolutionized operations and boosted productivity

VasyERP Working for You to Build Your Business Super-Efficient

Get product demo so you’re confident it’s the right fit. stay focused on what you’re good at and let us improve your store experience and efficiency.

17,000+ Customers

4.8 Google Review

FAQ! Need Help?

We've got you covered

The Steel ERP has modules like accounting, CRM, Supply chain management, production, inventory, compliance, and warehouse management. The custom steel manufacturing ERP can further add/drop any feature/module as required.

Steel manufacturing ERP takes care of the following processes and production types:

- Beneficiation and Palletization

- Sponge Iron DRI

- Steel Melting

- Blast Furnace

- Rolling Mill

- Ferro Alloys

- Steel Wire Products

- Steel Pipes

- Galvanized and Color-Coated Sheets

Inventory Management :Solution: Steel ERP systems offer real-time inventory visibility which protects steel production from stockouts and overstocking.

Sustainability Compliance :Solution: Modern ERP solutions track environmental metrics and aid in regulatory compliance.

Workforce Management :Solution: The steel industry is labor-intensive. ERP solutions optimize workforce management with shift scheduling, labor allocation, and labor compliance.

Energy Management :Solution: ERP monitors energy use in steel production and helps in reducing energy costs.

Product Traceability :Solution: Steel manufacturing ERP enables end-to-end traceability of raw materials, simplifies recalls, etc.

Complex Supply Chain Management :Solution: Steel manufacturing ERP provides end-to-end visibility across the supply chain. It enables real-time tracking of supplier schedules and supplier performance.

Production Efficiency :Solution: ERP integrates production planning and execution. It synchronizes activities, allocates resources, and enables better planning.

Quality Control :Solution: ERP for the Steel industry enforces quality standards (department-wise, process-wise, etc.), implements inspection procedures, and identifies issues early.

Regulatory Compliance :Solution: ERP assists in meeting the steel industry’s regulations, compliance tracking, and monitoring features.

Cost Management :Solution: ERP offers real-time insights into costs, accurate allocation, and analysis. This helps improve margins and the bottom line.

Demand Forecasting :Solution: ERP uses data and analytics to predict market needs, aligning production with demand.

Equipment Maintenance :Solution: ERP includes maintenance modules for proactive scheduling, maximizing uptime, and extending machinery lifespan.

Customer Relationship Management :Solution: ERP integrates customer data and communication tools, improving service and relationship management.

Raw Material Price Volatility :Solution: ERP provides visibility into material costs and trends, aiding informed decision-making.

To select the best steel manufacturing ERP, consider the following steps:

- Know your needs: Understand your requirements for production planning, inventory management, and quality control. Consider process control, raw material management, and regulatory compliance. Choose an ERP that addresses your specific pain points.

- Integrations and modules: Ensure seamless integration between procurement, production, inventory, supply chain, CRM, and finance. Look for an ERP that connects processes like smelting, casting, rolling, heat treatment, and quality control.

- User-Friendliness: Select an ERP with an intuitive interface that all staff can easily navigate, avoiding steep learning curves and complicated dashboards.

- Provider Expertise: Evaluate the ERP provider's experience, domain knowledge, and understanding of industry challenges. Ask how their system handles production scheduling, capacity planning, energy management, and regulatory compliance.

- Customization: Seek an ERP that offers custom features to address your plant's unique workflows and processes. Be wary of providers who refuse customization but consider rational explanations for limitations.

- Cost Considerations: Assess all costs, including implementation, operational, licensing, training, and support fees. Remember that experienced providers may charge more but offer greater value.

- Scalability: Choose a cloud-based ERP that can grow with your business, handling more data, users, and transactions without major investments.

- Real-time Analytics: Look for robust analytics with customizable dashboards and detailed reports for informed decision-making.

- Mobile Access: Select an ERP with mobile apps or responsive web interfaces for on-the-go management.

- Industry Compliance: Ensure the ERP supports steel industry standards, regulations, and safety protocols, aiding in documentation and compliance reporting.

- Vendor Support: Evaluate the ERP provider's onboarding, technical support, and system updates. Consider available training resources and user communities to help your team fully utilize the ERP.

- Robust tracking of raw materials and managing iron ore, coal, and other raw materials

- Easy furnace operations, optimized blast furnace, and electric arc processes

- Top quality control, consistent steel quality through every production stage

- Optimized production schedules to maximize furnace utilization

- Reduced waste and improved yield rates

- Enhanced quality control measures to minimize defects and rework

- Optimized production planning and production runs for maximum efficiency

- Efficient inventory tracking with real-time monitoring of raw materials, work-in-progress, and finished goods

- Full compliance management with industry regulations and standards

- Proactive maintenance scheduling of critical equipment to minimize downtime

- Cost savings for each production process and product

- Uninterrupted supply chain with seamless coordination with suppliers

- Better decision-making with advanced analytics

- Better energy management and sustainability tracking

- Improved workforce management leads to increased productivity