Complete Guide to Reducing Stock Shrinkage with Smart Inventory Systems

November 13, 2025

Stock shrinkage reduction is one of the biggest challenges retailers and wholesalers face today. Even a small percentage of loss due to shrinkage can significantly impact profits, cash flow, and forecasting accuracy. This in-depth guide shares how businesses can achieve stock shrinkage reduction with modern technology. It discusses key drivers, financial impacts, and the power of a smart inventory management system that communicates in real-time, is automated, and has analytics. And, learn the steps related to implementation, best practices, and how VasyERP's cloud-based software can help reduce inventory losses more effectively.

Stock shrinkage is one of the most stubborn problems in retail and wholesale operations. It can impact your profits without you knowing, create data discrepancies, and make forecasting more of a challenge than necessary.

Luckily, the good news is that modern technology has provided businesses with the means to gain total control over the business’s inventory. A smart inventory management system gives you the ability to track each product in real-time and immediately identify discrepancies. It also helps businesses take proactive measures to reduce losses before they occur.

In this complete guide, we will walk you through everything there is to know about reducing stock loss – causes for shrinkage and financial impact. We will also be taking you through the advanced features of a smart inventory system. We will also outline a detailed step-by-step action plan and best practices. Finally, we will take you through a detailed case study of a retailer who achieved success in preventing losses with VasyERP’s cloud-based inventory software.

This guide is ideal for anyone who wants to enhance operational efficiency and ultimately achieve total inventory shrinkage prevention.

Shrinkage is the gap between the inventory that you have recorded as on hand and the inventory that physically exists. This includes stock that has been lost, stolen, damaged, or misplaced at any point along the supply chain.

If left unchecked, shrinkage can have a significant impact on your bottom line, skew your inventory records, and ultimately reduce profits.

The first step in effectively preventing inventory shrinkage is understanding what causes stock loss. Shrinkage is not a one-off instance; it is usually categorized as a combination of human error, theft, and process deficiency. By understanding where losses occur more frequently, businesses can take the necessary steps to fortify their retail stock management software and systems of controls.

| Cause | Key Understanding |

| Theft and Shoplifting | One of the biggest causes of shrinkage is particularly in retail. |

| Employee Theft | Internal theft often happens over long periods without anyone noticing it. |

| Administrative Errors | Mistakes are made during manual entry or when reconciling poor data. |

| Supplier Fraud | You get fewer products than you are invoiced for. |

| Product Damage or Spoilage | Especially common in certain categories of perishable products. |

| Not Scanned or Misplaced | Very common during busy periods of restocking. |

Each of these causes are very minor on their own, but combined, can create a tremendous leakage of income. A smart inventory management system will detect, analyze, and prevent these issues through automation and real-time visibility, making relatively simple work of reducing inventory loss and maintaining a positive profit margin.

Even a minor percentage toward shrinkage becomes significant. Research in worldwide retail found that an average shrinkage rate of approximately 1.4% of sales results in 1.4 million in lost revenues for every 100 million in revenue.

For small businesses and retailers, this loss can severely affect cash flow. Shrinkage not only directly impacts cash flow but also causes variable demand forecasts and purchasing decisions that lead to under-stocking. Implementing a smart inventory management system can begin to eliminate these inefficiencies and help establish a leaner inventory loss.

Manual inventory management through spreadsheets or physical counts is cumbersome, tedious, and very prone to error. The key drawbacks of traditional inventory management practices are:

Traditional inventory management systems can only tell you what your inventory should be at any moment in time, not what you actually have in stock. The difference between these two data points could be costly to your company.

An intelligent system streamlines inventory management with automation, cloud technology, and data analytics. It offers visibility in real time and automated stock counts. It also helps in key interactions with POS and accounting, among others.

Systems like VasyERP are more than just counting inventories. They allow optimization of inventory control systems, predictive forecasting, and immediate alerts for discrepancies in stock to allow full control and accountability of the inventory.

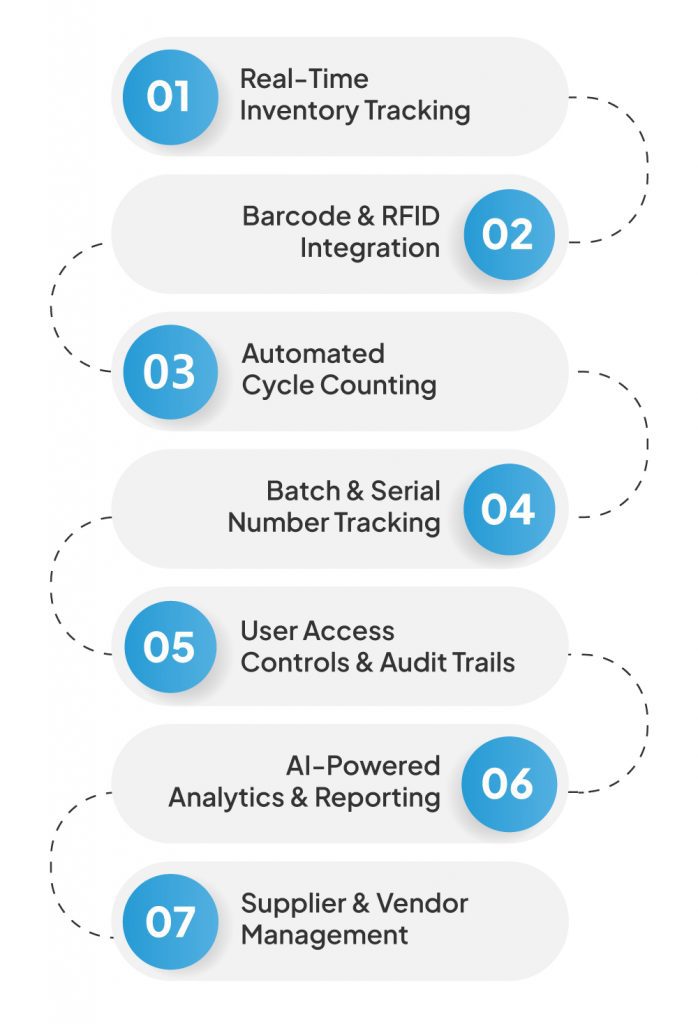

Reliance on guesswork is no longer possible to optimise stock; businesses need precision, automation, and visibility. A smart inventory management system applies both advanced tools and intelligent capabilities that can eliminate losses before they even occur. Let us break down the capabilities that promote effective stock shrink and give you complete control of your inventory process.

Through continuous tracking between the warehouse and stores, you will know exactly what is in stock and its location. Updating inventory items in real-time immediately identifies missing and misplaced items to minimize loss.

By using a barcode generator for inventory, you can assign each product a unique barcode or RFID tag to simplify stock tracking and reduce human error. This ensures faster checkout, better traceability, and accurate documentation of every item

Rather than waiting for an annual audit (and the chaos it induces), automated cycle counting facilitates the continuous auditing of your stock levels. This not only minimizes disruption, but it also creates earlier identification of discrepancies.

In industries dealing with perishable goods, or serialized products, batch tracking provides you with traceability. As an added benefit, this will also help mitigate spoilage, counterfeit items, and items received that do not match the shipment.

All actions are logged. Access controls prevent unauthorized users from manipulating stock information, and audit trails show what actions were taken by whom, and when – a required function for fraud detection.

AI actively forecasts demand patterns and recommends interventions. Using inventory shrinkage prevention analytics, inventory decisions become data-driven and controls are enhanced.

Having vendors be held accountable at every level requires an efficient vendor tracking system. A smart system like VasyERP allows you to maintain a supplier database, map each product’s link to a supplier, and alert you when issues arise in a supplier-delivery.

All of these functions work synergistically and create a powerful ecosystem that is oriented by data and focuses on strengthening your inventory control system. When functions are implemented using a strong platform like VasyERP, businesses gain real-time sight, transparency, and automation – all vital functions for consistent inventory shrinkage prevention and efficiency for operational functions across every sales and storage point.

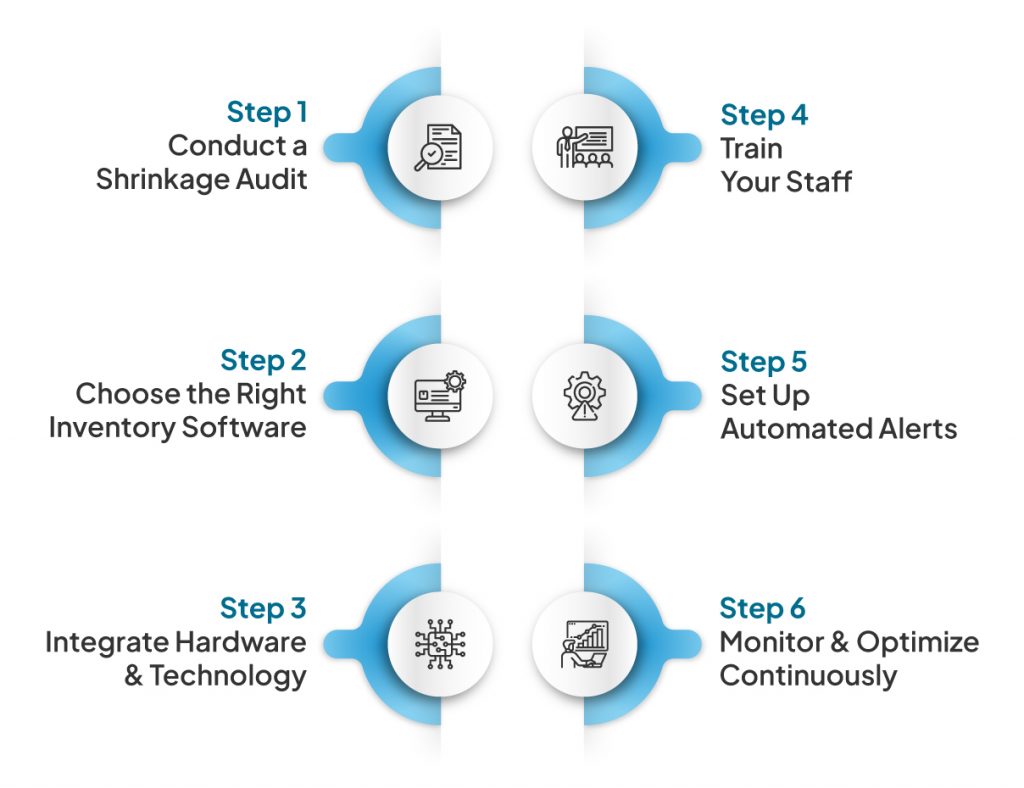

Adopting a smart inventory management solution exceeds simply installing software; it’s a shift in how your business manages stock control, tracking, and analysis. Following a methodical procedure to cost control inventory, inventory shrinkage prevention works to ensure you are intentionally utilizing technology that will align your team with the best practices in your industry, and will put the infrastructure in place to sustain cost control for the long term to come.

You will want to update and calculate your current shrinkage rate and identify the causes of inventory shrinkage. Keep the history logs, damage, and audit reporting to point out important areas at risk of loss to focus on.

Find a solution such as VasyERP with an expandable capability, real-time stock control, and multi-location solutions. Additionally, you will want to ensure that the solution can work with your POS, CRM, and accounting systems.

Add when necessary barcode scanners, RFID systems, and POS terminals to the retail stock management system. Hardware integration will make for easy updates and centralized data.

Shrinkage will only be resolved by people, not technology. Conduct sufficient training sessions to share how the hardware and software should be managed and utilized in the system with responsible associates.

Set up alerts for inventory variances, edits that are not authorized, or large volumes of reductions in inventory by using alert options. Alerts provide pre-warning notifications of possible theft or bad employees.

Make sure to regularly sample analytics reports to look for trends or repeatable pain points so you can leverage that data to update your processes and stock shrinkage reduction in your operation.

By following these workflows, you systematically create a connected data-based system that minimizes manual process utilization and maximizes accuracy in all aspects of the sourcing supply chain. Each element from Audit process creation to automating the data quality process is an additional granularity to your ability to reduce inventory losses while maintaining total visibility. With technology like VasyERP, it is easier than ever to obtain seamless, smart, and scalable control over your inventory.

Minimizing loss is not just placing cameras or locking the storeroom – it is about creating a culture of control, transparency, and accountability. Coupling and leveraging intentional, purposeful, effective processes with intuitive, modern technology will lead to significant loss prevention. Below are some tried and true best practices for local and an accountable inventory control system in place to ensure every item controlled is accounted for:

By habitually implementing these tried and true practices, your operational capacity creates a proactive measure in waste prevention instead of a reactive measure in incident response after the fact has occurred. In tandem with intelligence tools like VasyERP’s inventory management system, these processes ensure both classic and real-time visibility and accuracy for the prevention of long-term inventory loss or waste across all operations.

The return on investment from intelligent inventory systems is quantifiable in both cost and efficiency. Companies typically experience this ROI in 6-12 months through:

Intelligent systems like VasyERP also provide intangible ROI – improved decision making, enhanced employee accountability, and the knowledge that your inventory is always under control.

Over the next 10 years, inventory management will become increasingly intelligent:

As innovation never stops, VasyERP and tools like it are setting new benchmarks by utilising innovative strategies for inventory shrinkage prevention, as businesses look to remain steps ahead of losses.

Inventory shrinkage is not a necessary business expense. With the help of our technology, you can take control and transform inventory chaos into clarity. A great inventory management system gives you real-time visibility and accurate forecasts while providing automated alerts to help you avoid losing money or products before they happen.

If you’re an SME, MSME, or a retailer experiencing issues with too much or too little stock – inconsistent online and in-store stock counts – it is time to transition to the cloud.

After extensive research, VasyERP has developed a Cloud-Based Inventory Management Software to simplify, automate, and optimise your operations by including:

17,000+ merchants trust VasyERP to reduce inventory losses and help with 99% error free.

Take the first step forward to simplify inventory and improve the profitability of your stock management. Gain effortless control and complete transparency with VasyERP, the best retail stock management software for modern-day key decision-makers.

1. What is stock shrinkage, and how much does it cost retailers?

Stock shrinkage refers to the loss of relevant inventory due to theft and administrative mistakes. This can cause discrepancies between inventory on hand and inventory on record. Retailers worldwide, on average, lose approximately 1.4% of total annual sales due to shrinkage. These concealed costs can amount to billions of dollars each year, ultimately resulting in lower profits and less cash flow.

2. How do smart inventory systems help reduce stock shrinkage?

Smart inventory systems allow businesses to automate stock tracking so that they can record properly and consistently every stock movement in real-time. They also provide immediate notifications of any anomalies, prevent duplicate entries, and trigger alerts of anything else aberrant. Centralized visibility and audit trails enable businesses to detect theft, mistakes, or wastage early on in the process, while smart systems allow brands to attempt inventory shrinkage avoidance with confidence while having the ability to track data and inventory counts through all channels and warehouses.

3. How does RFID tracking differ from barcode tracking for inventory management?

Barcodes rely on visual scanning, and therefore, it may require physically scanning each stock item to see what might be on hand, which can be tedious. While RFID, or Radio frequency identification, reading can scan all items at once and is much faster and accurate for bulk inventory stock amounts, rather than individually scanning each item, because visual scanning requires line-of-sight. RFID provides significant time savings, reduces manual entry errors, and increases the efficiency of your overall inventory control system.

4. How long does it take to see ROI from a smart inventory management system?

Most companies see returns on investment within six to twelve months of implementing a smart inventory management system. The ROI comes from shrink reduction, greater accuracy, optimal stock levels, and lower labor costs. Furthermore, automation speeds up operations, results in overstock and stockout avoidance, and provides analytics that add to profitability and ensures ongoing sustainable operations.

5. Can small businesses afford smart inventory systems to mitigate shrinkage?

Yes. Current inventory software, such as VasyERP is specifically designed to be cost-effective and scalable forall SMEs, MSMEs, and startups. Businesses can deploy applications in the cloud, and there are no major costs for hardware or setup. Businesses can start small, scale with their growth, and still access substantial added automation and analytics that will reduce loss in their inventory without exceeding their budget.

6. How does VasyERP assist businesses in reducing inventory shrinkage?

VasyERP prevents shrinkage through automation, transparency, and control. VasyERP will track inventory in near real-time across multiple locations, maintain digital audit trails, and restrict unauthorised access in real time. AI-powered reports instantly highlight theft patterns and stock mismatches. Features such as supplier mapping, batch tracking, and mobile audits ensure the utmost accuracy in retail stock management software.

7. Does VasyERP provide real-time alerts for stock discrepancies and theft prevention?

Indeed, VasyERP comes with real-time notifications of low stock, negative stock, or unusual stock movement. This allows your business to act immediately to resolve an example any discrepancies and additionally to avert the risk of theft or errors in stock movement. These notifications, combined with user access control, provide improved transparency and accountability, as well as constant monitoring, which is, of course, essential in any effective loss prevention plan to reduce stock shrinkage.

Retailers have a large number of SKUs; therefore, smart...

December 15, 2025

Inefficient inventory management is the main cause of h...

August 13, 2024