ERP Software for Sweet & Namkeen Businesses: Why It’s Essential for Multi-Outlet Operations

February 5, 2026

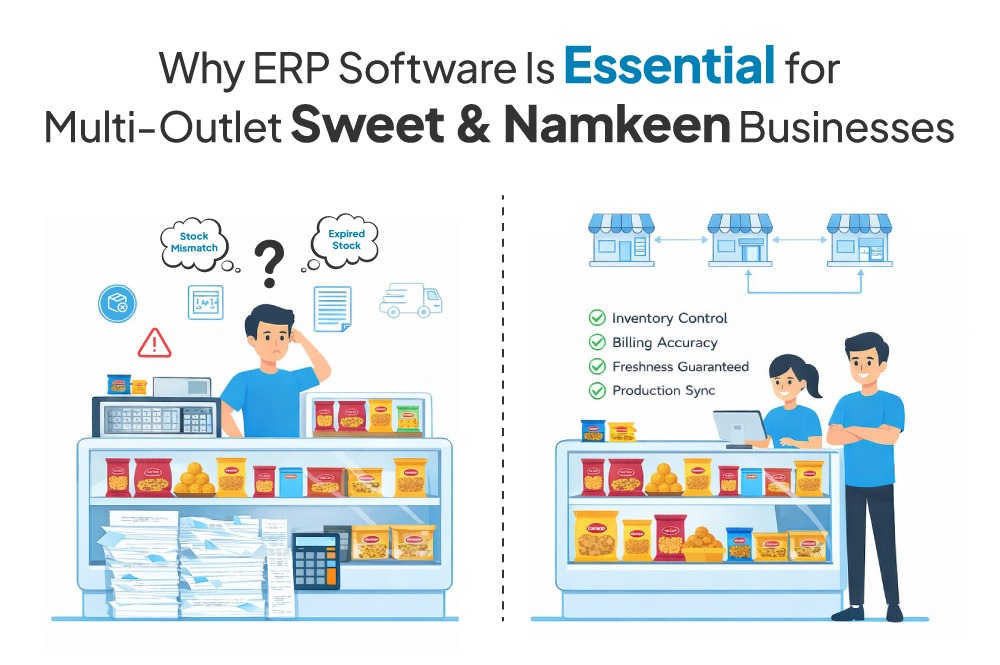

ERP Software for Sweet & Namkeen helps brands in the sweet and namkeen industry overcome challenges while scaling to multiple outlets such as inventory wastage, expired stock, GST compliance issues, and inconsistent product quality. ERP software for sweet and namkeen manufacturers helps centralize production, inventory, billing, and recipe management across all outlets. By connecting sales with production and providing real-time visibility, ERP systems enable sweet and namkeen brands to scale efficiently, maintain freshness, and improve profitability. This blog explains how ERP software supports smooth multi-outlet growth for sweet and namkeen businesses.

The growth of the Sweet and Namkeen brands in India has taken them from being small, family-owned businesses to becoming regional and national franchises with many physical locations. As competition intensifies for customers, increased demand and consumer demand for hygienic production have led these brands to recognize that scaling their business is not as easy as just opening additional stores. The method of tracking and managing production/delivery of products was manual. This involved using handwritten documents and communicating via telephone. Moreover, many of the processes included delays and stock waste. It also involved loss of income opportunities due to a lack of control and visibility.

With the advent of technological solutions, specifically ERP systems, companies that manufacture sweets and namkeen will be able to effectively integrate their production. In addition, by implementing an ERP System, Sweet and Namkeen brands have the potential to expand their businesses in a cost-effective manner. This is done while providing their customers with product consistency and profitability across all locations.

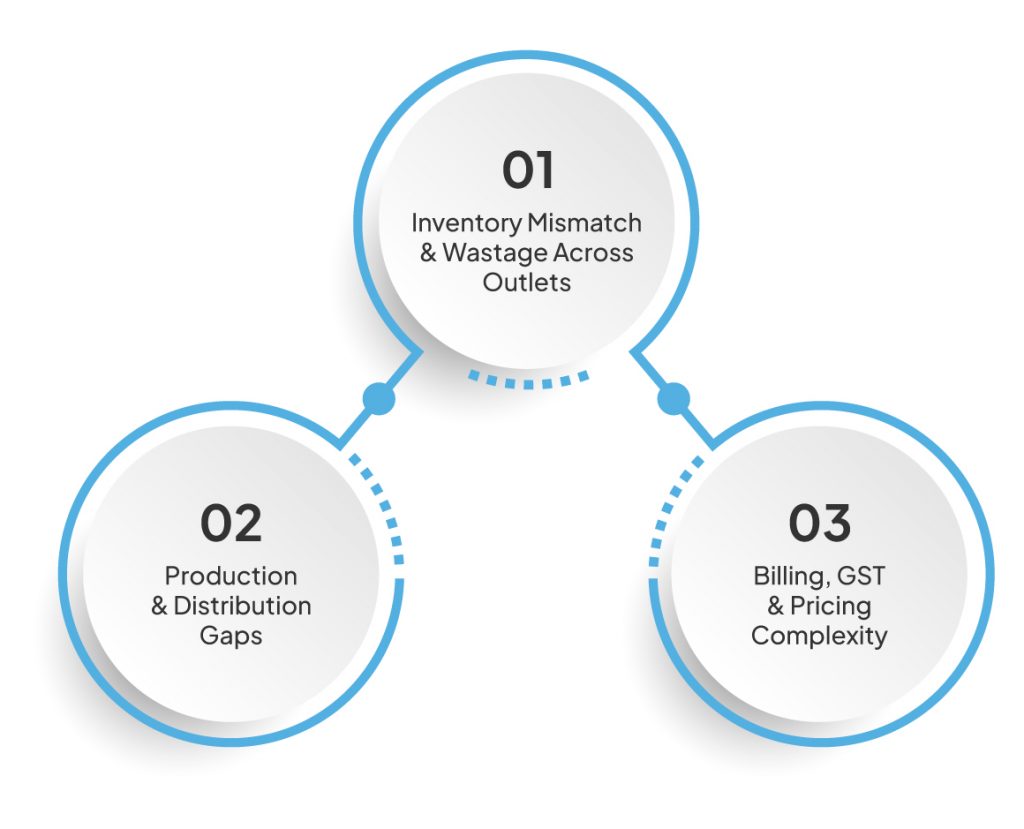

Scaling up a business that sells traditional sweets and namkeen products is complicated. Expansion introduces challenges related to the movement of goods (inventory), the management of inventory and prices to ensure compliance with local laws and regulations, etc. The primary challenge is the need to ensure that each store is performing consistently while production and procurement remain centralised. If there is limited access to information about SKUs that are selling quickly, the level of wastage, and how the entire range of products are selling, companies will struggle with difficult challenges to reduce their costs and to give customers an excellent experience.

The sale of sweets and other products is driven by seasonality. Each location has its own cyclical variations in demand for these products. And therefore, it is important to have visibility of available inventory at all the stores. This should be done so that each store can have inventory that matches its local demand. Since inventory is not visible from a centralised point of view, it is common for a store to over-stock on slow-moving goods. Consequently, stores may suffer from stock-outs and/or significant wastage stemming from having to manually track inventory levels.

Producing products for multiple locations requires consistent procurement, batching, packaging, shipping and replenishing. When the processes between production and outlets are not automated, there are frequent disruptions. These disruptions are in the schedules of dispatching products to the outlets. Consequently, the outlets do not receive products on time.

Plus the cost of logistics increases. Therefore, it is not possible to ensure product freshness through the delivery of the products to the outlets. Therefore, businesses that are growing need to ensure that the inbound and outbound distribution of their products has been synchronised. This should be done to support their ability to fulfil daily demand in an effective manner.

The introduction of multi-outlet billing creates an additional complication with each store using different GST categories, product pricing and discounting structures. This complication increases the opportunity to incur billing errors and miss GST filing deadlines. Plus outlets can have inconsistent pricing too. The manual billing process will also create longer customer queues and increased service times. It can also create the potential for financial discrepancies which can affect the growth of your business.

Traditional methods of tracking your business’s financial information cannot provide the necessary functionality to manage the complexity involved in growing your Sweet and Namkeen brands. An ERP System provides you with a centralized location. This dashboard helps manage aspects of your business operations. This includes; Production, Outlets, Procurement, Billing and Compliance. By utilizing an ERP system you will have a better understanding of your inventory levels. Businesses will also be able to standardize the overall experience. This will allow you to reduce excess inventory and run a more profitable operation in multiple locations.

ERP systems allow brands to track their inventory throughout their entire supply chain including Outlets, Kitchens and Warehouses. Having a centralised location to monitor inventory usage helps provide stock alerts and create replacement schedules. It also provides brands with better control over their procurement process and assists in eliminating guess work. Now this subsequently reduces the risk of stock-outs and wastage. Plus it provides consistent product availability across all locations.

Storeowners can view the sales performance of every store, including the most selling products for that store, inventory levels of products and identify store trends through the use of real-time dashboards. The leadership team can make informed decisions about its stores without physically having to oversee them. This will further help eliminate any guesswork in maintaining/store opening hours.

By matching the production capability of its products with actual sales, a brand can reduce its wastage and increase its margins. ERP systems share daily sales with production facilities. This further allows them to create batches and utilise materials effectively. Moreover it helps schedule deliveries according to sales. This allows for fresher products to be in stores and higher margins.

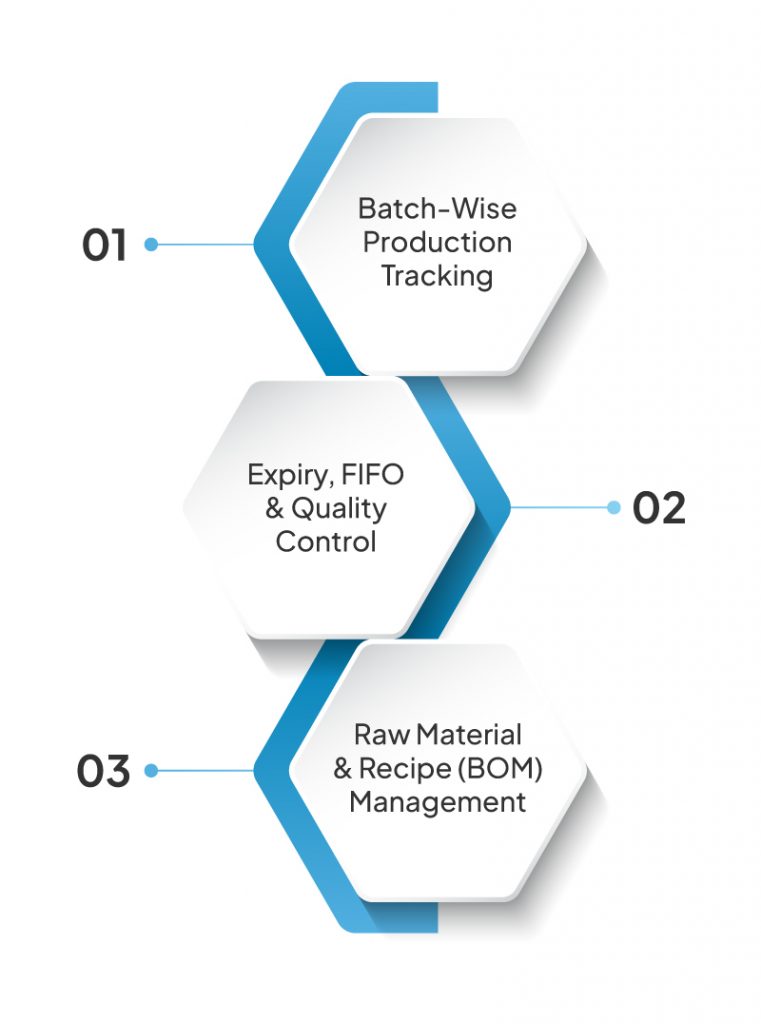

In contrast to grocery items that can be stored indefinitely, traditional sweets and many namkeen SKUs are very sensitive to time, temperature, and production batching processes. Knowing how long a product will be sellable for will ensure retailers never run out of stock due to expired products while upholding all health & hygiene standards..

Batch tracking assists production teams in ensuring consistent taste, texture, and quality of products at each of their locations. Additionally, it provides traceability in the event of a complaint about a product. Many premium brands utilize the batch tracking system as a tool to modify their recipes and lessen the variation in products. Additionally, batch tracking can be used by brands to manage the effective use of batches. It can also help track the expiration dates of sweets effectively. This will further increase food safety and quality.

Shelf life varies greatly for different types of sweets; for example, kaju katli and peda have a much shorter shelf life versus traditional boondi laddoos. As such, ERP systems enforce the FIFO and expiration date control systems. This is done to prevent customers from receiving any expired products. Furthermore, during peak festive seasons, the products are produced in larger volumes. Moreover, customer expectations for freshness are higher. Hence, the ERP systems assist in managing the batches of sweets and their expiration dates.

When a recipe is created, the raw materials must be measured accurately, such as Ghee, khoya, dry fruits, spices, and sugar. ERP systems have the BOM (Bill of Materials) feature to provide standardization of recipes. It also includes the overall management of the total cost of the products sold at all locations. This ensures that the brand produces all sweets according to the recipe. And therefore provides a similar taste of its products while maintaining the consistency of the brand.

As businesses grow, it is necessary to implement standardisation processes for their POS, pricing, billing, and compliance due to the potential for inconsistency in manual billing systems and compliance issues across an organisation with multiple locations, for example, stores located in various cities/states. The implementation of an ERP solution automates the invoicing process and integrates with the POS. It also provides GST reports and thus shares much needed control and compliance.

Integrating the billing and POS systems within the ERP allows for faster customer service, provides transparent pricing, and enables the synchronisation of data between multiple outlets in real-time. Customers experience better queue management during peak hours. This is done especially during busy periods such as festive seasons when there may be an increase in foot traffic. Also, the ERP system has a sweet shop inventory management software solution that helps in accurately allocating stock. It also helps in enabling quick billing at the sweet shop counter.

As the ERP system generates GST compliant invoices, sales registers, HSN summaries, and Tax Reports without requiring manual entries, this reduces error and reduces the risk of non-compliance penalties for businesses. For example, if a company operates in many different cities, it allows them to keep their pricing standard. This is done by updating the price categories and discounts from one centralised location. It further allows for faster and easier reporting on sales figures and accounting figure. It also helps with inventory accuracy through the integration of the ERP system with the sweet shop inventory management software.

Making expansion decisions based only on intuition could lead to an unsuccessful outlet. ERP data provides a better understanding of outlet performance and more. This makes the scaling of an outlet a strategic rather than an experimental decision.

The ERP dashboard provides visibility into profitability as well as SKUs with the highest sales and highest waste, and contributions regarding margins, enabling business owners to determine which locations need assistance. In highly competitive markets, insights such as these should be used before opening a new outlet.

Forecasting demand is critical to avoiding overproduction and stock-outs, while seasonal sales, festival peaks, weddings, and events that are specific to a geographic area can have a major impact on customer purchasing patterns. ERP systems provide production planning tools based on these historical demand trends. This thereby reduces waste and improves all of the delivery rates.

Sweet and Namkeen Companies have unique requirements that cannot be met with generic ERP systems. They depend heavily on the type of SKUs and recipes that take into account shelf life in their production process. A generic ERP system is not suitable for running a sweet and namkeen business.

When evaluating ERP software for a sweet and namkeen business, there are several essential features that you should look for, including: batch tracking, alerts for expired products, BOM analysis, GST/GST applicable pricing, multiple locations ability to work with on multiple sales channels (POS) and the ability to create and manage a master production plan (MPP).

If you are a small business and are thinking of growing your business, it is advantageous to choose an ERP system like that of VasyERP that is scalable. It should offer training and provide local support as part of your contract. Additionally, having an easy-to-use interface will be beneficial. This is because it will increase the amount of staff time spent on training and onboarding staff. The advantages of having an ERP system will allow you to leverage compliance reporting. It will also allow you to leverage analytics and supply chain logistics to grow your business while also improving your profitability.

VasyERP provides customized ERP solutions for sweet & namkeen manufacturers. Our ERP systems offer features such as inventory management alongside GST billing and production planning. It also includes recipe-based manufacturing and support for multi-outlet management, among others. VasyERP provides sweet & namkeen manufacturers with the tools necessary to grow their business. VasyERP provides manufacturers with transparency by providing each production unit with a retail outlet integrated through a cloud dashboard. We ensure that all of our operations are transparent and have real-time visibility into production levels. This visibility allows manufacturers to reduce waste, improve product quality and scale profitably at their best.

To grow a sweet & namkeen manufacturer’s business, it is important to establish an operational system like that of VasyERP that is disciplined, fulfills the requirements of standardized recipes, provides visibility of all production units and outlet managers. The use of manual processes will reduce the manufacturer’s ability to achieve quick turnaround times. It will also increase waste and create compliance bottlenecks (as the brand expands into new cities/regions). An effective ERP system will help eliminate these operational inefficiencies and provide a strong foundation for continued profitable growth. ERP systems will enable sweet and namkeen manufacturers to grow much faster. This growth will be achieved with a higher degree of confidence than a traditional model. Sweet and namkeen manufacturers will have access to use advanced analytics when all inventory, billing, GST, production and sales analytics are integrated into one system. This is done to assist in making decisions about expansion and pricing while maintaining product quality & consistency.

1.Why do sweet and namkeen businesses need digital systems instead of manual operations?

Manual processes can only grow to a certain level before the inability to scale is caused by delays, mistakes and limited visibility. Multi-outlet companies need synchronized inventory and production. They also need the right invoicing at the outlet level. Digital systems will provide the accuracy that creates operational efficiencies. It also enables faster decision-making and consistent compliance across outlet locations. This is carried out to grow sustainably and profitably.

2. How does technology improve freshness and product consistency?

Technology enables brands to track production batch information and shelf life. It also smartly enabls to track the demand at outlet locations. Now this is done by utilizing tech-enabled systems to prepare, schedule, and dispatch their products every day. All of this is carried out while creating a structure for planning the expiry of their products. As a result, brands are able to maintain the same taste and quality of their products which increases customer loyalty.

3. Can ERP systems handle festive or seasonal demand spikes?

Yes, ERP solutions will analyze past purchasing and using patterns, peak sales, and buying trends for an event or season (i.e., a wedding month or holiday season) to more accurately forecast their production requirements and ensure that there are no stock-outs and that when product demand tapers off, they have reduced their excess inventory. This is very important for sweets and namkeen brands, which experience a lot of seasonal peaks throughout the year.

4. Are ERP platforms suitable for small or single-outlet sweet shops?

Yes, they can! A sweet shop that is smaller still needs the ability to collect digital invoice payments, control recipes, be compliant with GST, and keep track of its inventory. As the shop grows into more than one location, the ERP system can grow with it and allow the ability to manage multiple stores without redoing the ERP. If you begin using the ERPs early, then they will help you scale your business up and not create operational limitations as time goes on.

5. How long does it take to implement an ERP for sweets and namkeen businesses?

The amount of time to implement the ERP system will depend on the size of the business. It will also depend on the number of locations and how many modules are being used. Moroever how much data has to be imported into the system plays a key role too. A smaller company may be ready to go live in a matter of weeks, but a multi-city chain may require additional time for training and testing. Most new systems are trying to implement the system in phases. Now this is done to minimize disruption to business operations during the entire implementation process.

6. What benefits do owners get from real-time analytics and visibility?

Real-time analytics provide owners with the capability to track their business performance. They can track it from anywhere in the world and see their store’s profitability. They can also use analytics to assist in their inventory planning and see the trends in each individual SKU. With these insights, owners can plan for their inventory better and provide better negotiating leverage. This is done when purchasing raw materials and creating strategic plans for their business growth. The use of data to make decisions keeps the sweet shop’s outlet competitive. It also helps perform operationally efficiently in a larger geographical market.

No doubt, ERP software is one of the specific parts of ...

July 17, 2023

Enterprise Resource Planning (ERP) is a software applic...

January 27, 2025