Why Correct UOM Management is Critical for Retail & Distribution?

January 7, 2026

The correct management of UOMs (Unit of Measure) is a very important yet often disregarded foundation of successful retail and distribution operations. The blog explains that when UOM errors are made the result is inaccurate inventory, incorrect pricing, extended operational lead times, and unmonitored financial losses. The blog also details various common UOM issues that cause businesses to miss out on sales revenue, and the impact of ineffective UOM management on a business's overall performance. In addition, the blog discusses and highlights the importance of technology and the role that ERP systems such as VasyERP play in helping businesses automate UOM processes to reduce manual errors and to enable growth that is scalable and sustainable.

When people think about growth within the retail or distribution industry, most people think only about sales revenue and the number of customers added to their customer base. However, there is one aspect of every successful retail or distribution company that is arguably more important than everything mentioned above. This is how well a company measures, tracks, and manages its products. Unit of Measure (UOM) management may sound operational. It may even sound boring, but it quietly influences profitability, efficiency, and customer satisfaction.

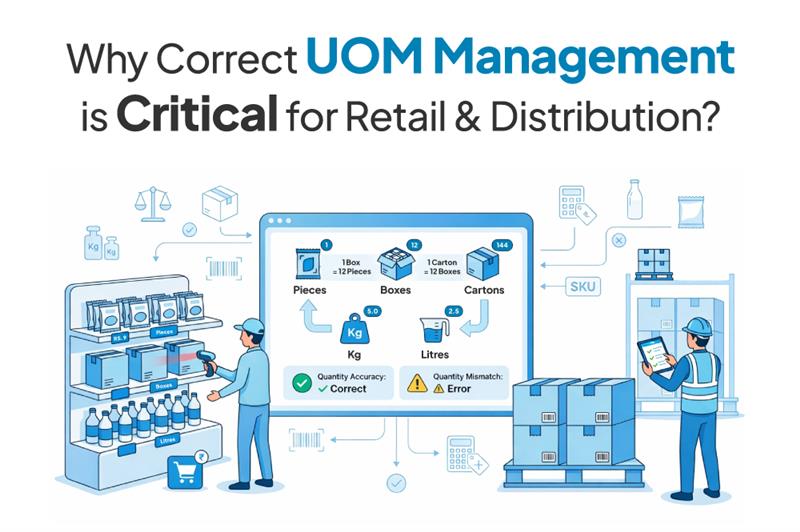

Retailers and distributors deal with a number of products every day. These move across multiple unit pieces and boxes, and more. When these units are not managed correctly, even the best supply chain strategies fall apart. Stock mismatches and incorrect pricing all stem from poor UOM handling. Furthermore, even over-ordering and accounting errors are also rooted in poor UOM handling.

As businesses scale, Unit of Measure (UOM) complexity increases. Without structured systems and technology support, small UOM errors multiply into large operational losses. This blog explores why correct UOM management is critical for retail and distribution businesses. It also takes you through how getting it right can directly impact growth, margins, and customer trust.

UOM (Units of Measure) management relates to how a company determines and applies UOMs across the entire supply chain. This depends upon what point in the supply chain the product is in when it is acquired, stored, or sold.

For instance, let us take an example of a distributor. He will acquire the cooking oil product manufactured by the company in 48-gallon drums which is measured in gallons. He will then transfer the cooking oil to his warehouse in 55-gallon drums. And finally sell the product in 15-ounce bottles to his customers.

Unit of Measure (UOM) management will also ensure the proper mapping and conversion. It will also ensure the synchronization of UOM data. This is generally between purchasing, inventory, sales, logistics, and accounting functions. It will also keep all UOM definitions the same throughout the supply chain. It also includes pricing, taxation and reporting for the appropriate UOM. If this is not done correctly, there is a very good chance that different teams will use different measurements for the same product. And this would further lead to confusion and additional costs.

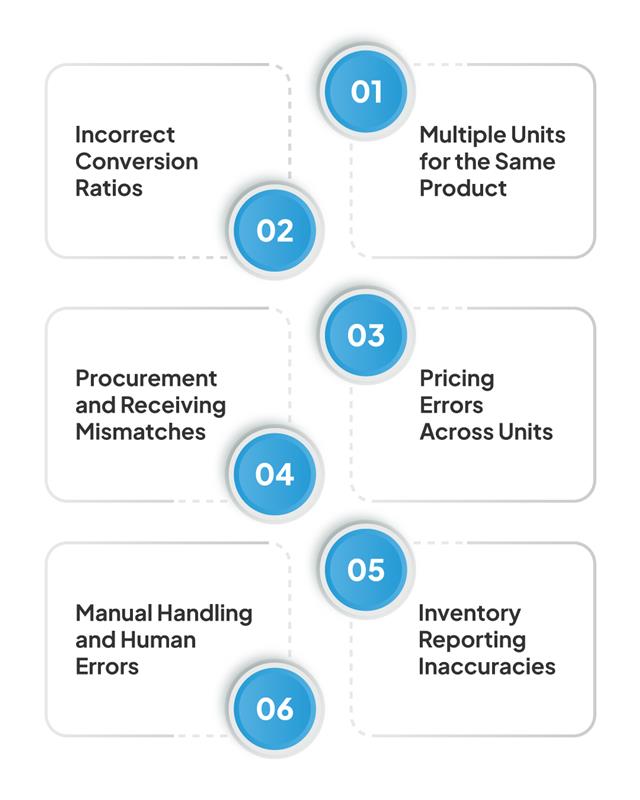

Many times, Unit of Measure (UOM) issues go unnoticed until they affect revenue, inventory levels or consumer satisfaction. These types of problems become increasingly challenging to resolve as products grow in volume and as firms expand. There are several other common UOM-related issues that retailers and wholesalers encounter.

Many items can be sold as pieces, boxes, cartons, or by weight. Without a way to track the number of items in each unit of measurement, different departments often have difficulty. They have difficulty tracking the quantity of items on hand and more. This, in turn, can cause problems for the Purchasing, Receiving, and Sales departments. This is due to discrepancies in inventory levels resulting from inefficient operations.

If the conversion factors between the units of measure are not correct or inconsistent, then there is a large chance of considerable errors in your physical inventory that will continue to compound over time. For example, if a carton-to-piece conversion factor is incorrect, there will be no accurate count of inventory. Over time, these small errors can lead to stockouts or financial errors.

Conversely, the pricing of product(s) can vary greatly depending on the type of unit of measure that you are using to determine the price of your product(s). When the Unit of Measures (UOMs) are not defined correctly, the business can either undercharge or overcharge the customer. This can negatively impact the profit margin. Furthermore, it can create inconsistencies around the point-of-sale (POS) systems and the accounting records.

Many suppliers deliver items in a different unit of measure than their purchase order. When this happens, receiving departments document incorrect quantities. This is because of a lack of alignment with UOM on the purchase order. This further complicates the reconciliation of supplier records with their account.

Inventory reports are based on accurate UOM information. If several different units of measure are combined or not converted correctly, these reports become unreliable. Using incorrect or incomplete data to make strategies will lead to bad decisions.

Proper Unit of Measure (“UOM”) Management is an essential operational function of doing business and has critically important ramifications for a company’s profitability, efficiency, and scalability. In retail and distribution, small UOM mismanagement can ripple through procurement and inventory. Interestingly it can also ripple through sales, and financial departments.

If not addressed, these issues will continue to grow over time. Finding solutions requires the establishment of systematic processes. It also requires the establishment of systems that support UOMs and technology-based solutions.

Proper Unit of Measure (“UOM”) Management is an essential operational function of doing business and has critically important ramifications for a company’s profitability, efficiency, and scalability. In Retail and Distribution, small UOM mismanagement can ripple through procurement and inventory. Interestingly it can also ripple through sales, and financial departments.

Properly managing UOMs provides businesses with more control over their inventory. It also provides control over costs and customer commitments. The following are some examples of how Proper UOM Management provides tangible benefits.

Proper Unit of Measure (UOM) ensures that all UOMs within a business’s unit of measure are consistent, accurate, and correctly recorded, especially when managed through inventory management software. When UOMs are correctly documented across all UOM definitions of a business, UOM users have greater visibility into their stock levels. They are also able to track their inventory more accurately using inventory management software. Therefore, decreasing discrepancies and preventing stock from being over or under stocked. In addition, when UOMs are accurately documented, businesses will have more accurate inventory data. They will further be able to use this data to better forecast product demand.

When Unit of Measure (UOM) used in the Procurement, Warehousing, and Distribution functions are accurately identified/defined, all functions along the supply chain will operate more effectively and efficiently, therefore enabling businesses to operate smoothly. Plus it will also lead to fewer disputes between UOM users and their customers. And as a result, less time spent on reworking orders. The appropriate level of UOM consistency enables increased collaboration. It also simultaneously improves coordination between suppliers and logistics providers.

When it comes to poorly managed units of measure (UOMs), they tend to result in excessive procurement, waste, shrinkage, or even incorrect billing – all of which create hidden costs for a business. Conversely, if UOMs are managed correctly, a company can have better insight into the true cost of its goods per unit of measure. It will also help reduce the actual leakage through the supply chain. Thus ensuring the company’s margins remain intact.

Accurate quantity and pricing create a foundation of trust for customers. When customers receive exactly what was ordered without any shortages or overcharges, satisfaction is increased. And there are fewer complaints, returns, and disputes.

Although it is possible to do unit-of-measure (UOM) management by hand on a small scale, as the number of transactions grows, it becomes very inefficient to continue to manage uoms manually. Technology is essential for creating and automating. It is also very important for managing standardised processes for UOM management across retail and distribution. Using modern ERP software to manage UOMs across all aspects of a business allows a company to define multiple UOMs for each product. It helps determine conversion ratios and apply them consistently. This is applied throughout the purchasing, inventory, sales and accounting functions within the company.

As a result, manual UOM calculations are replaced with automated calculations. This reduces the chance of errors and enables real-time data synchronisation across all departments. Technology solutions like VasyERP do just that for businesses engaged in both retail and distribution. VasyERP allows businesses to manage all types of Unit of Measure (UOM). VasyERP covers all types of UOMs used for purchasing and selling products. This is done while providing businesses with accurate UOM reporting. VasyERP ensures that UOM Consistency can be maintained at every point of operation. It thus creates increased accuracy and increased scalability for growing businesses.

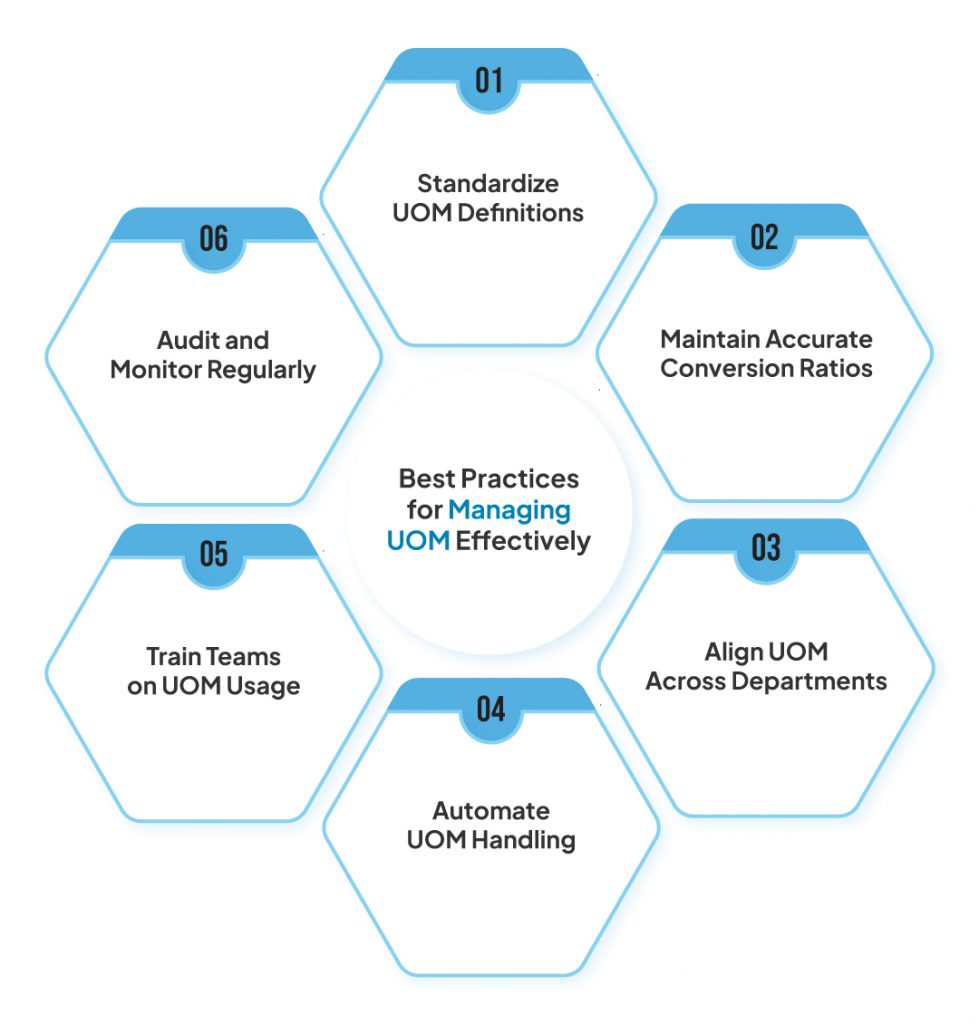

UOM (unit of measure) management requires a clear set of processes combined with internal discipline and support from your systems. When a business considers its UOM as a strategic function, it is much easier for that business to scale effectively while minimizing operational friction.

Every product should have a primary and secondary unit defined for that product. By doing so, there will be no confusion among teams. This is because when different teams use different units for the same product, it will reduce confusion about units of measure.

Once established, conversion ratios should be reviewed regularly. Even minor mistakes can introduce daily inaccuracies into both your inventory and cost calculations over time.

The various departments involved in Procurement, Inventory, Sales & Finance should be aligned to use the same UOM structure. This will ensure a consistent view of all the processes that take place throughout the supply chain.

Calculating UOM manually increases the chances of mistakes. Using automation via an ERP system provides both accuracy and speed to the UOM management process and the ability to scale up or down.

Training employees in how to use UOMs within the software is imperative, through proper training you will help to prevent misuse, overriding and to limit the need for manual adjustment.

Regular audits will reveal discrepancies, and monitoring UOM data will help ensure long-term accuracy and operational discipline.

If businesses adopt all the best practices mentioned above, they can greatly reduce UOM-related risk. Using an ERP platform such as VasyERP can help to automate these best practices. It also helps reduce the amount of manual work necessary to implement them.

Retail and distribution growth rely on operational scalability, and accurate unit of measure (UOM) management creates a pathway for retailers and distributors to grow their product lines, expand into new markets and increase the volume and speed of transactions without adding disorganization to their operations.

Through accurate UOM data, businesses improve their forecasting abilities. Consequently, businesses are more capable of planning their inventory and purchasing efforts. Accurate Unit of Measure (UOM) data also drives better financial reporting. This is because it gives business leaders a better understanding of their business expenses, margins, and performance.

When a business is successful, its operations quickly become complex. UOM controls allow businesses to grow without creating inefficiencies or losses. Strong UOM operations provide businesses with a stable operational foundation. This is indeed required to maintain long-term profitable growth.

Although UOM management is not the most visible aspect of retail and distribution, it is one of the most critical. Accurate UOM data, along with UOM management, enables a retailer or distributor’s ability to increase customer satisfaction. This is ideally done by increasing inventory accuracy and cost containment.

Businesses that do not properly manage their UOM typically experience the emergence of unforeseen losses. They also undergo operational inefficiencies and difficulties associated with growth. Conversely, businesses that invest in well-structured UOM processes combined with UOM-related software can be assured that their businesses will be more successful. They also have the assurance that their business will be better organized and more confident.

Using an ERP solution like VasyERP allows a retailer or distributor to seamlessly manage a multitude of UOMs. By managing UOM accurately, retailers and distributors are positioning themselves for long-term success.

1. Why does UOM matter for retail?

The Unit of Measure (UOM) is important because retailers sell the same items in multiple package sizes. They also sell the same items in several different types and measurement units. Properly managing UOM allows for the correct pricing of products. It also helps in the accurate tracking of inventory and easy billing. If UOMs are managed properly, it prevents retailers from experiencing stock mismatches. It smartly helps prevent the various different pricing disputes and customer complaints. Simultaneously, it helps cover the inconsistency across POS, records of inventory, and financial reporting.

2. How does poor UOM management affect inventory?

Poorly managed Unit of Measure (UOM) create inaccurate stock counts. It further results in inaccurate conversions and therefore unreliable inventory data. It also leads to ineffective replenishment cycles, all due to a lack of trusted inventory data. Furthermore, it leads to difficulty forecasting. The best part is that it increases the cost of holding excess inventory.

3. Can ERP systems really handle complex UOM structures?

Modern ERP applications have evolved to support complex UOM (Unit of Measure) and UOM-related needs in retail. It also supports the fields of distribution and e-commerce. ERP systems support multiple units of measure for every product. This include automated converted UOM ratios for each product for ease of use at all levels of the organization. It also provides for the consistent application of UOM.

4. Is UOM management important for small distributors?

Definitely, Many smaller distributors believe that Unit of Measure (UOM) management becomes a concern only when the company grows. But early mistakes may create problems that could last for years. Even if the number of products that are sold and shipped is small, the use of different measurement units, such as pieces, boxes, weight, etc., is common in the industry. Therefore, properly defining UOM from the very beginning will help prevent billing errors.

There is no doubt that quick commerce has been a great ...

April 23, 2024

Retailers, micro, small, and medium enterprises (MSMEs)...

November 23, 2025