How VasyERP Helped

- Daga Brothers

- Daga Brothers

Streamline

Dry Fruits Operations

- Daga Brothers

- Daga Brothers

Learn how a legacy dry fruits business modernized inventory, packaging, employee workflows, and deliveries using VasyERP

Summary

Daga Brothers struggled daily with managing inventory, packaging workflows, and delivery delays. Following the implementation of VasyERP, all activities were consolidated onto one platform, greatly decreasing inventory mistakes and enhancing packaging effectiveness. Having real-time visibility across different locations has simplified operations management, aiding business growth while ensuring compliance

About the Client

Daga Brothers is a dry fruit retailer and wholesaler located in Pune, India. The company was founded in 1963 and has a long history of distributing and stocking dried fruit in both online and offline (retail) markets. Daga Brothers has consistently focused on quality control in addition to having an extensive amount of inventory. They have also become increasingly modernized as the retail experience evolves.

Sector

Operating In

Business Model

Challenges

Problem Statement

Our client Daga Brothers has experienced considerable growth in their dry fruit retail and wholesale business, significantly increasing the volume of raw materials and packaged goods handled. This growth revealed heavy reliance on manual workflows, causing inventory inaccuracies, LOT tracking difficulties, disorganized packaging and delivery processes, and fragmented delivery management. These issues created delays, errors, and hindered scalability across all locations.

Inventory & LOT Management Challenges

With a lack of real-time visibility into both raw,packaged and damaged inventory, the company experienced a high degree of inventory mismatching between physical and system inventories. Lost LOTs were tracked manually resulting in reconciliations errors. The missing traceability from purchase to the finished good, limited quality controls, accountability, and end-to-end visibility of stock consistently.

Location & Stock Transfer Issues

With numerous storage options, i.e., warehouses and cold storage inventory controls were fragmented. The processes for moving inventory between locations internally were manual, resulting in errors, delays. No process existed for tracking or reconciling differences in inventory while moving inventory, therefore, it was difficult to track and reconcile the differences in the inventory.

Production & Packaging Inefficiencies

The transition from raw materials in bulk to finished products was unstructured and not standardized. Quantity errors were created on a frequent basis due to calculations being done manually per kilogram, instead of using a software application to automate calculations. There was no standardized production process with recipe-based production or repeatable process on how to produce packaged products, especially for kit products or complex multi-material conversions.

Barcode & Labeling Problems

There was no consistency in how barcodes have been produced and utilized across different products. Many important details like LOT numbers, bundled expiration dates, and applicable MRPs did not appear on packaging labels, as well as there was missing integration between the weighing scales used for loose items and the barcode systems.

Delivery & Payment Challenges

Delivery order communication was done manually through phone call or messaging and created confusion and delayed the deliveries for delivery personnel and customers alike. Without a standard way to capture customer feedback into the proof-of-delivery processes, disputes for undelivered products increased. Electronic payment records do not have real-time data making it hard to reconcile electronic with cash payments and affect the transparency of financial transactions.

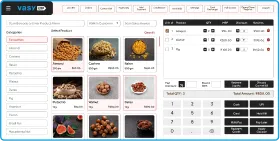

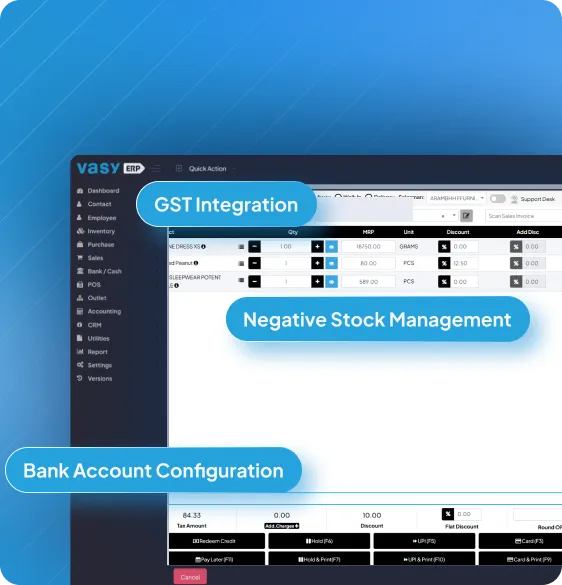

POS & Compliance Issues

There was poor visibility in the components for GST on the Point of Sale increasing the risk of non-compliance. Also, the invoicing process for SEZ sales was not done automatically - this resulted in needing to manually process these accounts - as well as, to not having the visibility of negative stock levels this created a situation where we could oversell. Also, not being able to automate the selections for banks to bill - this resulted in a slower operational billing process, which increased the risks of errors in accounting.

Transform your inventory, packaging, and delivery workflows with VasyERP’s comprehensive ERP solution

Book a DemoSolutions Offered

VasyERP resolved the dry fruit wholesaler's operational challenges with a comprehensive ERP system managing all dry fruit processes. This created consistent, standardized workflows across inventory, production, packaging, and delivery.

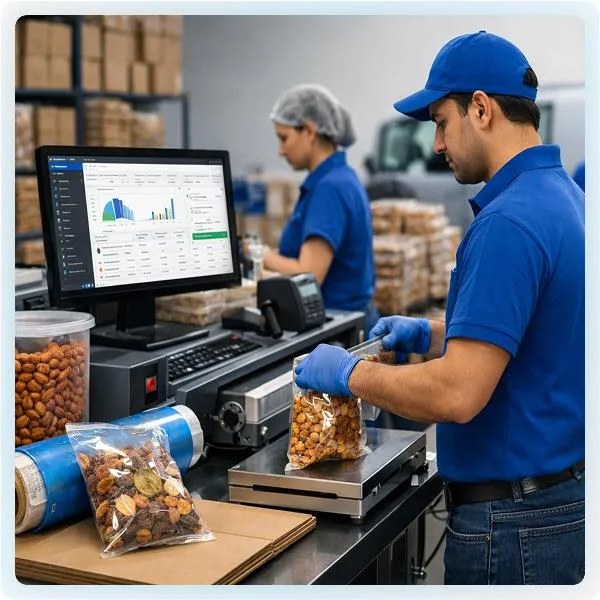

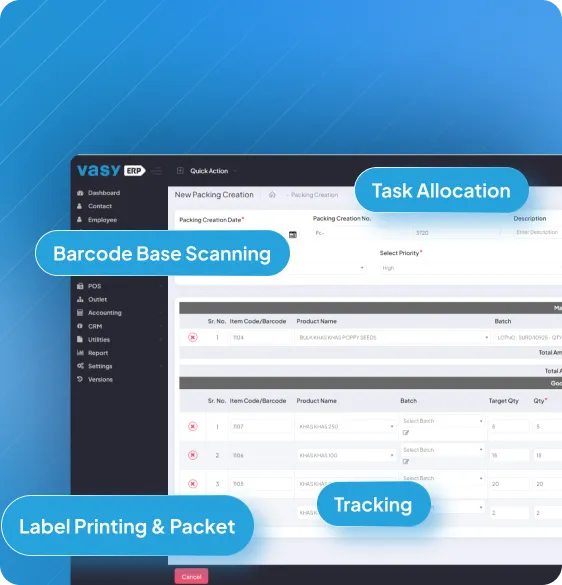

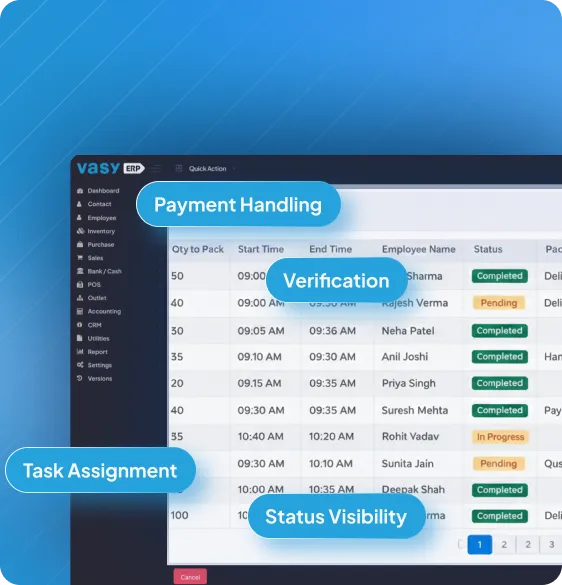

Through the VasyERP system, Daga Brothers can assign packaging tasks directly to their staff using an Android App dedicated to packaging tasks. Each task will contain important information. This would include product information, LOT numbers, and total quantity to be packed. This removes the need for management to provide both verbal instruction and the need for employees to ask questions at each step of the process.

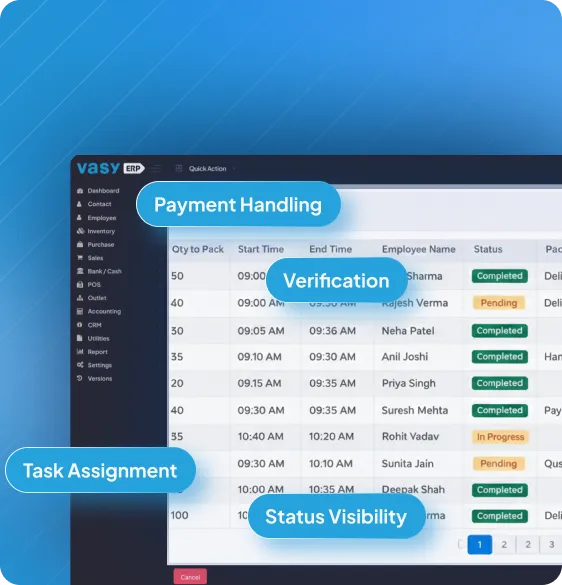

VasyERP automatically tracks both the start and end times of tasks and allows Daga Brothers to see the length of time taken to package each product. This level of tracking will give Daga Brothers complete visibility into the time taken to package products. It would also allow them to accurately measure employee productivity, creating a more accountable environment.

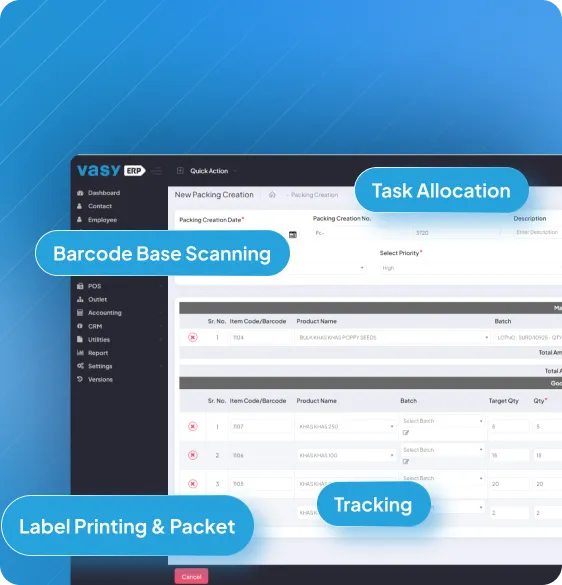

The use of barcode-based lot scanning enables employees to confirm that they are using the proper raw materials and ensures the ability to trace all raw materials back to lot numbers throughout the distribution system. By confirming the lot number before beginning the task, the employee also ensures that the correct stock is used.

The label printing and packet counting function allows an employee to print a label each time a packet is generated and to count the number of packets generated. The employee will provide accurate inventory updates and maintain consistent physical stock and electronic records by using these functions.

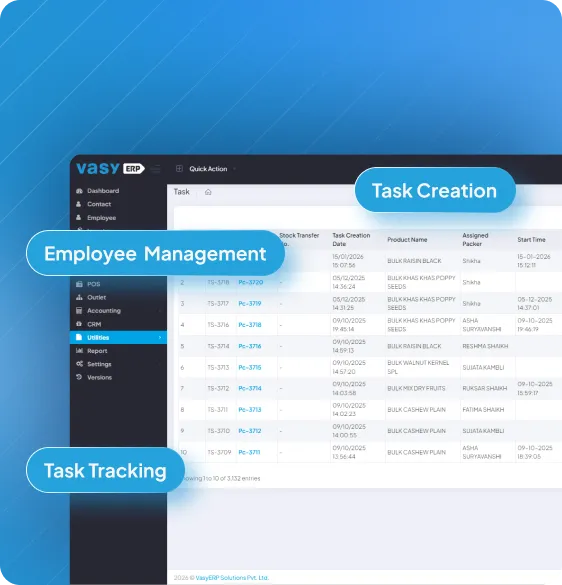

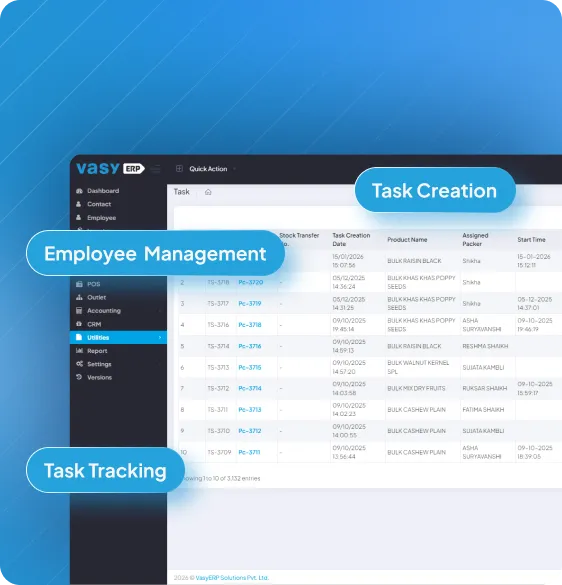

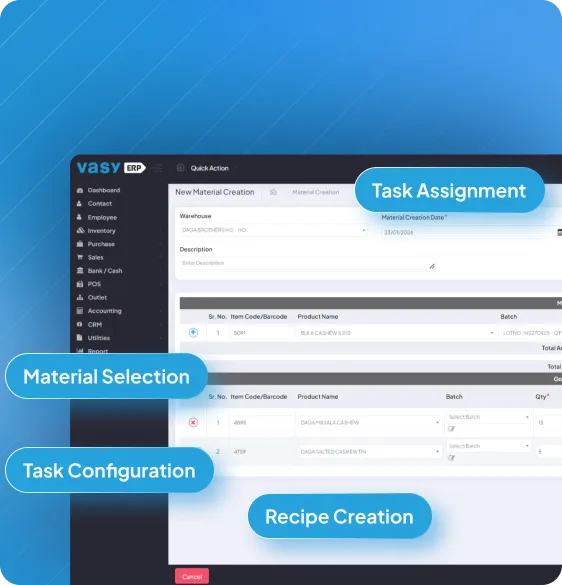

By creating tasks from within the ERP system, admins can select parent and child products, lot stock, quantity, and packaging type for package creation. Admins can further categorize packages from within the task creation screen. This can be done as "normal packaging tasks" or "materials creation tasks" based on the type of production required.

After a task is created in the task management system, it will then be assigned a priority rating and a due date for an employee. This allows for keeping employees' schedules open when assigning work to them. It further allows them to complete tasks faster. And at the same time, it allows the definition of specific responsibilities of employees for completing tasks.

As Administrators are working with the task management system and completing tasks from other employees, they have access to live status updates regarding the task, who is completing the work, when the work was started, when it is expected to be completed, the current status of the task, including variations in task execution compared to what was originally expected.

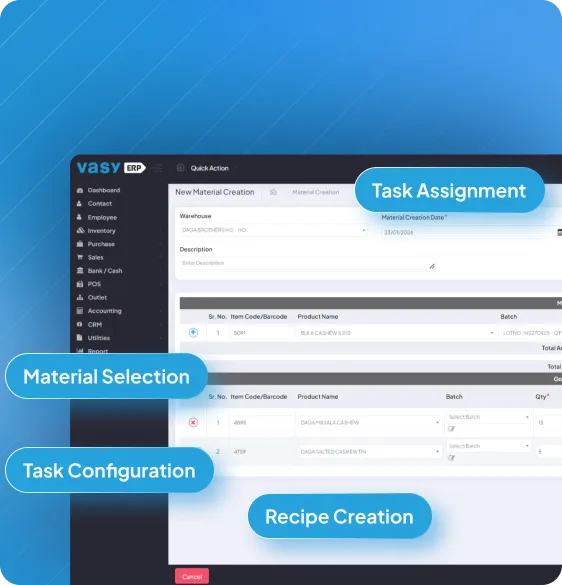

ERP admin users have access to a pre-made recipe list, allowing them to identify and select one of these recipes to manufacture materials. A recipe includes detailed information such as the raw material types and, quantity of each type of the raw materials. The administrator can quickly process the production of materials by using a pre-created recipe. This can be done without having to set up the process for every single use of a recipe.

A task is assigned to an employee by an administrator, indicating when the administrator expects the task to be completed, how urgent it is for the administrator. This structured task assignment helps distribute the workload for employees. It also allows administrators to know when to expect the tasks to be completed.

After an employee submits a request for a task to be assigned to them, the system will automatically assign the material-making task to that employee. The task's specifics will be delivered to the employee's mobile application instantly. It will thereby eliminate the need for employees to follow up via phone calls or emails.

In cases where a new recipe for a material is required, but no recipe exists, the Administrator may enter a new recipe into the task management system and upon saving, the new recipe will become part of the recipe database for subsequent execution of the materials used in the recipe.

When a customer places an order for home delivery through the retail POS, the order is automatically assigned to a delivery agent via the delivery application. Information related to the order is stored in the Enterprise Resource Planning (ERP) system. This makes it easy to see all the information at a glance.

Confirmation of delivery can only occur once the customer confirms the verification code (one time password or OTP) via SMS message is received; therefore, providing proof that the products were delivered accurately and will minimize disputes between customers and retailers about delivered products or misdelivered products.

The Delivery Application supports both cash and electronic payments, thus enabling the consumer to elect one form of payment over the other. Currently, all cash collections are processed in real time. This is done directly into the ERP system. The electronic payments can be processed via a quick response (QR) code. The QR code will allow the consumer to make efficient and accurate payments.

Administrators can access delivery information and view the status of orders, the method of payment for the order, and the assigned delivery staff directly in the ERP. This allows for greater control and increased reliability of customer service.

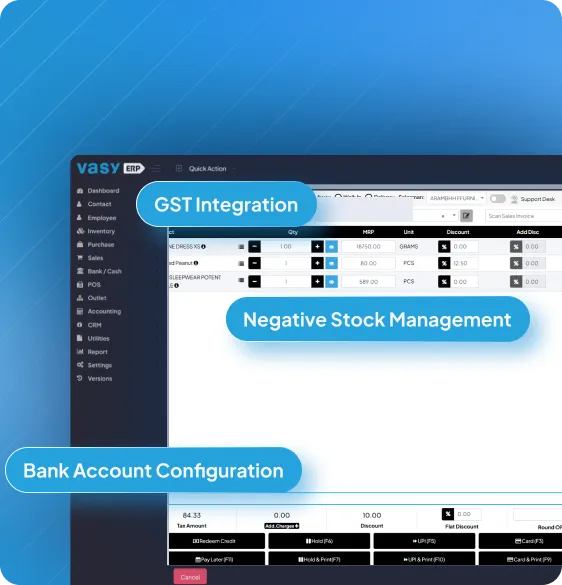

Automates GST GSTR2B/3B reconciliations to minimize manual errors with POS solution. Provides itemized GST breakdowns on Point of Sale bills for customer verification, auto-identifies SEZ invoices and mandates HSN codes for accurate classification and compliance.

Prevents order processing when stock is insufficient, blocking negative balances by category or individual product to maintain accuracy.

Auto-selects banks based on payment mode (card/UPI) for error-free routing. Supports multiple modes per bank with one-time setup, eliminating repeated selections for faster POS transactions.

Through the VasyERP system, Daga Brothers can assign packaging tasks directly to their staff using an Android App dedicated to packaging tasks. Each task will contain important information. This would include product information, LOT numbers, and total quantity to be packed. This removes the need for management to provide both verbal instruction and the need for employees to ask questions at each step of the process.

VasyERP automatically tracks both the start and end times of tasks and allows Daga Brothers to see the length of time taken to package each product. This level of tracking will give Daga Brothers complete visibility into the time taken to package products. It would also allow them to accurately measure employee productivity, creating a more accountable environment.

The use of barcode-based lot scanning enables employees to confirm that they are using the proper raw materials and ensures the ability to trace all raw materials back to lot numbers throughout the distribution system. By confirming the lot number before beginning the task, the employee also ensures that the correct stock is used.

The label printing and packet counting function allows an employee to print a label each time a packet is generated and to count the number of packets generated. The employee will provide accurate inventory updates and maintain consistent physical stock and electronic records by using these functions.

By creating tasks from within the ERP system, admins can select parent and child products, lot stock, quantity, and packaging type for package creation. Admins can further categorize packages from within the task creation screen. This can be done as "normal packaging tasks" or "materials creation tasks" based on the type of production required.

After a task is created in the task management system, it will then be assigned a priority rating and a due date for an employee. This allows for keeping employees' schedules open when assigning work to them. It further allows them to complete tasks faster. And at the same time, it allows the definition of specific responsibilities of employees for completing tasks.

As Administrators are working with the task management system and completing tasks from other employees, they have access to live status updates regarding the task, who is completing the work, when the work was started, when it is expected to be completed, the current status of the task, including variations in task execution compared to what was originally expected.

ERP admin users have access to a pre-made recipe list, allowing them to identify and select one of these recipes to manufacture materials. A recipe includes detailed information such as the raw material types and, quantity of each type of the raw materials. The administrator can quickly process the production of materials by using a pre-created recipe. This can be done without having to set up the process for every single use of a recipe.

A task is assigned to an employee by an administrator, indicating when the administrator expects the task to be completed, how urgent it is for the administrator. This structured task assignment helps distribute the workload for employees. It also allows administrators to know when to expect the tasks to be completed.

After an employee submits a request for a task to be assigned to them, the system will automatically assign the material-making task to that employee. The task's specifics will be delivered to the employee's mobile application instantly. It will thereby eliminate the need for employees to follow up via phone calls or emails.

In cases where a new recipe for a material is required, but no recipe exists, the Administrator may enter a new recipe into the task management system and upon saving, the new material recipe will become part of the recipe database for subsequent execution of the materials used in the recipe.

When a customer places an order for home delivery through the retail POS, the order is automatically assigned to a delivery agent via the delivery application. Information related to the order is stored in the Enterprise Resource Planning (ERP) system. This makes it easy to see all the information at a glance.

Confirmation of delivery can only occur once the customer confirms the verification code (one time password or OTP) via SMS message is received; therefore, providing proof that the products were delivered accurately and will minimize disputes between customers and retailers about delivered products or misdelivered products.

The Delivery Application supports both cash and electronic payments, thus enabling the consumer to elect one form of payment over the other. Currently, all cash collections are processed in real time. This is done directly into the ERP system. The electronic payments can be processed via a quick response (QR) code. The QR code will allow the consumer to make efficient and accurate payments.

Administrators can access delivery information and view the status of orders, the method of payment for the order, and the assigned delivery staff directly in the ERP. This allows for greater control and increased reliability of customer service.

Automates GST GSTR2B/3B reconciliations to minimize manual errors with POS solution. Provides itemized GST breakdowns on Point of Sale bills for customer verification, auto-identifies SEZ invoices and mandates HSN codes for accurate classification and compliance.

Prevents order processing when stock is insufficient, blocking negative balances by category or individual product to maintain accuracy.

Auto-selects banks based on payment mode (card/UPI) for error-free routing. Supports multiple modes per bank with one-time setup, eliminating repeated selections for faster POS transactions.

Implementation Highlights

Key milestones that show how VasyERP transformed daily operations through structured rollout and support.

Centralized ERP for Multi-Operations

A central ERP system was developed to integrate the retail, production, and transportation activities of the organisation, thereby eliminating "silos" of data to the point that the organisation's management team has access to a real-time digital representation of all items, tasks, and people involved in the operation.

Dedicated Employee Mobile Application

To facilitate the collection of labour information, a dedicated mobile app for Android devices was created specifically for packaging staff members to receive assignments, record LOT scanner activity, track labour time, and update output status in real-time.

LOT-Level Inventory Traceability

Utilising the LOT tracking feature of the system improves national, regional, or even local traceability from raw materials to finished products right through to sale per LOT. Every individual lot of raw and finished product movements has been recorded against the LOTs. It improved information transfer between all the partners.

Integrated Delivery Management

A delivery management system was integrated into the delivery app. This governs how all deliveries are assigned to route drivers along with how payments are received and one-time passwords (OTP) are sent for delivery confirmations. This allows for a higher level of transparency and accountability through the system.

The Impact

The introduction of VasyERP dry fruit operation management system allowed Daga Brothers to replace traditional operations with a structured, system-based digital platform. Packaging, inventory management, and delivery processes shifted from manual work to a single system. LOT-level tracking enabled complete traceability of raw materials and finished goods and improved stock verification accuracy.

System-generated tasks improved packaging efficiency and enabled real-time tracking of processing time. Clearly defined job instructions and better visibility for managers increased overall efficiency. Material creation for recipes ensured a controlled, repeatable process and consistent product quality.

Real-time inventory tracking improved accuracy across warehousing and retail facilities. ERP-based order assignment and OTP delivery confirmation enhanced the delivery process. Overall, the ERP reduced delays, increased accountability, improved compliance, and supported sustainable growth across retail and wholesale channels.

Packaging Process Efficiency

Inventory Accuracy Improvement

Reduction in Manual Coordination

Faster Task Turnaround

Error Reduction in Stock & Billing

LOT-Level Traceability & Compliance

VasyERP's implementation boosted operational efficiency for Daga Brothers which drastically reducing errors. The scalable infrastructure digitized key processes, freeing the business to focus on retail and distribution growth. Product quality remains assured alongside growing customer confidence.

Conclusion

As an organization with decades of experience, Daga Brothers needed an advanced solution to help modernize their business workflows. VasyERP provided a complete ERP Solution that digitized the company's most critical operations. This included inventory management, packaging, and delivery fulfillment seamlessly.

The VasyERP’s ERP software for dry fruit business streamline their operations. It also enabled an increase in transparency and created operational consistency. With implementation of ERP Software the client streamlined the complex workflows of packaging and material creation. Another benefit of the VasyERP implementation was that it provided a centralized order management system. This in turn increased the reliability of all the delivery operations and provided real-time updates.

A significant benefit of the VasyERP implementation was the increased level of accountability that Daga Brothers had at every operational step. Employees had strong directions to follow while being monitored on performance by managers in real-time, allowing decision-makers access to timely, accurate information to effectively plan and optimize their business operations for growth. Moreover, the modular and flexible design of VasyERP allowed the client to readily modify their processes. This was in line with changing conditions leading to increased compliance with regulations and continued standardization of their business processes.

With a fully implemented and supported ERP solution from VasyERP, you will have the ability to expand your business confidently with the support of an ERP solution that has been specifically designed for all areas of your organization.